Chris Railey

Well-Known Member

Not an introvert as much as just old and intolerant now.

Agree.Here is the Demo billet now. With the ends cut and billet halved we have about 5.750 X 1.750 x .750 thick.

View attachment 81911

Today I will start by fullering to width. Some watching this have not forged so I am gonna put a little basic forge work in too. Generally speaking to fuller means to widen a billet or to put a groove into something in a parallel direction. This squishes steel to the sides making the billet wider.View attachment 81915View attachment 81916View attachment 81917

You can see the parallel grooves have made the billet wider. We are over two inches wide now. The peen on a hand hammer moves steel in the same way. Use it as a straight peen (parallel) to make the steel wider or use it cross peen (perpendicular) to make the billet longer. If you watch FIF this is one of the main things that cause people to lose. They have no idea how to widen a billet with a fuller. They keep hitting it on drawing dies praying for width and end up with a long narrow thin billet. “For the lack of a fuller, the war was lost” -Chris Railey

Makes sense. I was just curious.Mainly because the can is still on there and sometimes when you squish that can it’ll roll in and cause a cold shut area on the edge so I always go about a half inch of total width wider than I need.

In truth I may have gotten away with a little bit of width gain from drawing the billet out and flattening it out but for educational purposes I went ahead and used my fuller so I could explain it.Makes sense. I was just curious.

Do you have flattening dies as well. ?Second step was to get length from the billet. For that I use drawing dies like this.View attachment 81918View attachment 81919

Yes, I make a few passes with either the fuller or the drawing dies then make a couple with the flat dies.Do you have flattening dies as well. ?

The main thing with using a press for forge welding is to not get too aggressive with your press. Two or three smaller squishes are better than one big squish. This goes double for pattern welded billets.Yes, I make a few passes with either the fuller or the drawing dies then make a couple with the flat dies.

You are most welcome. If you are ever in Georgia come on by you can try mine out. The only reason I have it is because I work The Master’s golf tournament for a large company every year and that gig is my tool money for the year.Man I wish I had a squish. Maybe someday. This is a cool WIP, thanks gor sharing!

What is SR??This is where I am at now. I managed to get it to about 13 long a little over 2 wide and I managed to get a little tang area forged before I ran out of gas. Since I am not going for propane today we will switch to SR from here.

View attachment 81922

Looks like a damascus paddle right now.

Sorry, Stock Removal. Normally I would have forged this closer to shape but since I ran out of propane and it is to thickness already, stock removal will work for the rest.What is SR??

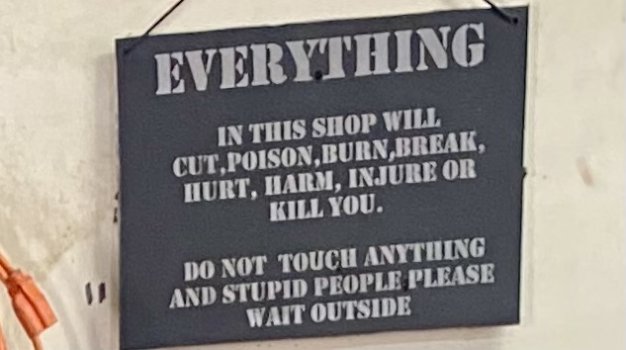

Love your shop sign. View attachment 81924

Yes, very appropriate!View attachment 81925

Funny what people notice in the background. Could you see the one on my press?

View attachment 81925

Funny what people notice in the background. Could you see the one on my press?