Ausbrooks

KNIFE MAKER

Had a few sitting around unfinished for a while so HAD to finish them before could move on to others. Leaving things unfinished drives me crazy and know am ill.

The utility is my EDC in CPM10V (I had an old stencil saying "Hi Performance CPM Alloy" that I to try- will not use again) with dymond wood, SS pins-tube, kydex sheath.

The skinner is D7 RC66 and took forever to finish grind, with moose antler scales and Lvless bolts. Sheath is 6-7oz with pigskin liner.

Since was a high RC blade, did some chop, tip prying, and bending and it maintained good edge, could not break with rough hand treatment.

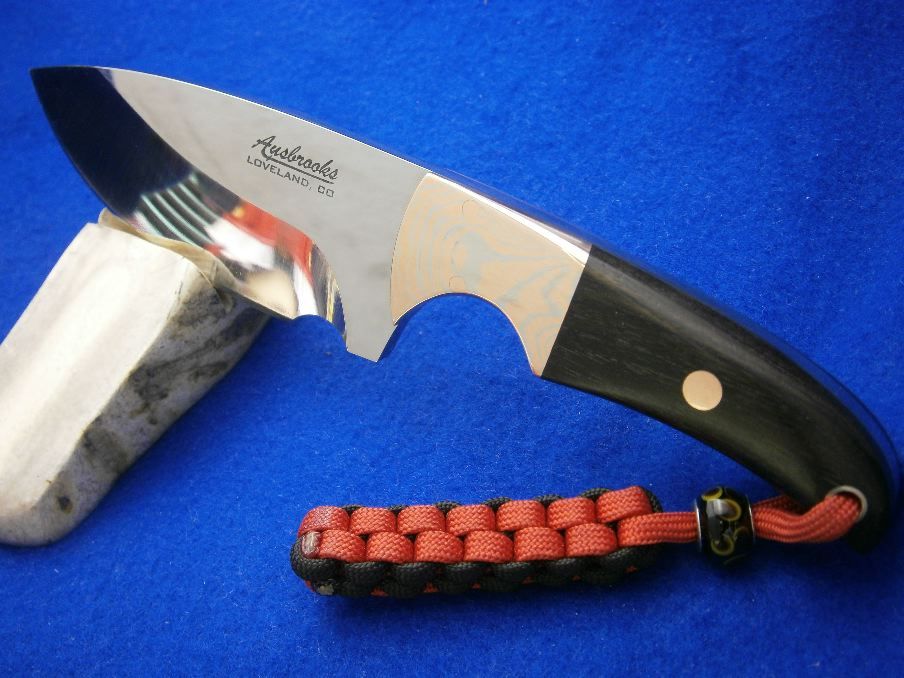

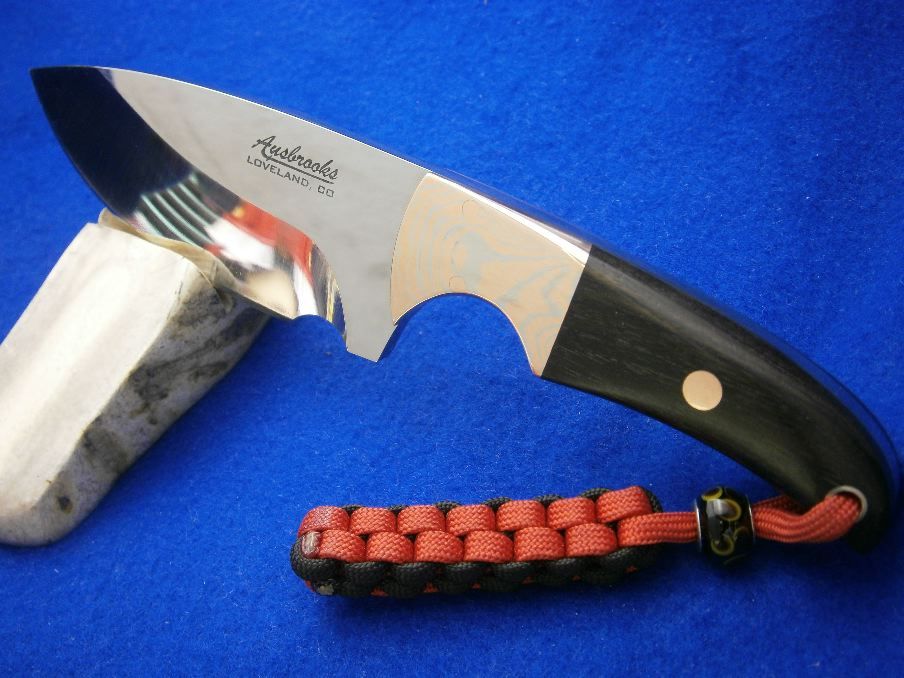

The hunter is BG42 RC62, my mokume (experimenting still), copper corby, SS tube, blackwood scales. Sheath is Long style with elk skin lining. Thanks for lookin' and comments welcome.

The utility is my EDC in CPM10V (I had an old stencil saying "Hi Performance CPM Alloy" that I to try- will not use again) with dymond wood, SS pins-tube, kydex sheath.

The skinner is D7 RC66 and took forever to finish grind, with moose antler scales and Lvless bolts. Sheath is 6-7oz with pigskin liner.

Since was a high RC blade, did some chop, tip prying, and bending and it maintained good edge, could not break with rough hand treatment.

The hunter is BG42 RC62, my mokume (experimenting still), copper corby, SS tube, blackwood scales. Sheath is Long style with elk skin lining. Thanks for lookin' and comments welcome.