Lol... I think this is how everyone does it. So stop trying to act like you invented this amazing thing. This guy told me it was a “Wilson Drop Point Hunter” when I first started. Kinda sad, John, kinda sad.

Now, if I may, I’d like to weigh in on this topic. And again, I would like to refer to John’s post; this time, however, I’d like us to consider John’s last paragraph.

I can't speak for John; so think of the following as my interpretation of his closing statements. I would also like to remind everyone of our recent commitment to honest, well-intended criticism. So here goes.

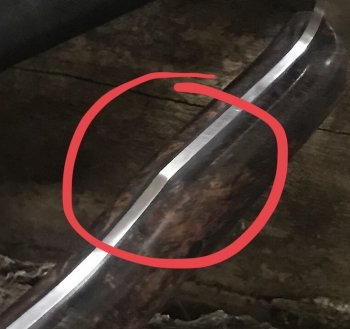

Even though he steals ideas and claims them as his own, like the scale pinning thing, he does have a truly unique, one-of-a-kind, signature of the one and only John Wilson. It’s all in his last paragraph. It’s beautiful. I’ll say brilliant. I’m stretching as far as I possibly can to say that it can be improved, critiqued, or more eloquently stated, but I simply must clarify his assumed jest. I think he meant - You have to do it this way, or it will never, ever come out right. It may come out close, but if you are truly trying to make a quality handmade knife, with symmetry in the contours- ya know, something worthy of your name, then bite the bullet, and properly attach the scales.

We all desire to make different types of knives. Some like the fancy stuff, some are neo-tribal, and so on. These guys can make anything, and that’s exactly my point. I read a post a while back where someone was asking about when should/does one consider themselves a knife maker. I thought about it for a while. Superficially the question is maybe silly, but I kinda have a habit of dwelling on things and meticulously picking apart an idea - well I say habit, but it’s more like my day job lol. So how do we measure a knife maker? Well, I think I may have found the answer to this very complex question. What John meant, and what the heck, I’ll speak for him, and the other John too lol may be expressed in one simple mathematical equation... The key that links my post, to the when am I a knife maker post, to JW to JD to all of our passions and desires lies in finding its solution. You have the rest of your life to finish this examination. Your time starts now.

1) LHS=RHS

Oh, and not to hijack a thread here, but are the JW-90’s really as good as what everyone is saying.