JawJacker

Well-Known Member

Well, Not a complete waste of time, I did learn a few things.

1. Nicholson file 1/4 thick

2. Annealed

3. Shaped and beveled drilled 1/4 holes 2

4. Normalized it, one round of 1650 then air cooled

5. Heat treated with Evenheat 1450 no soak, brine quench

6. 1 hr 400 degrees X2 for temper

7. Noticed I had some warpage 1/16 off in the handle area

8. placed it in the vise applied very little pressure to straighten .....and

9. PING :what!:

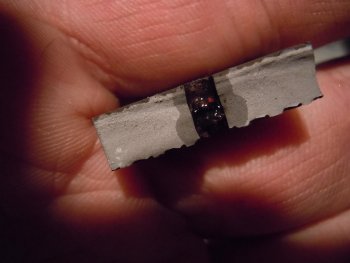

Anywho, How does my grain look?? Im going to test the pieces in the vise Monday to see what happens.

1. Nicholson file 1/4 thick

2. Annealed

3. Shaped and beveled drilled 1/4 holes 2

4. Normalized it, one round of 1650 then air cooled

5. Heat treated with Evenheat 1450 no soak, brine quench

6. 1 hr 400 degrees X2 for temper

7. Noticed I had some warpage 1/16 off in the handle area

8. placed it in the vise applied very little pressure to straighten .....and

9. PING :what!:

Anywho, How does my grain look?? Im going to test the pieces in the vise Monday to see what happens.