cardoso5fr

Well-Known Member

What you neet

Material

steel for blade

stainless steel plate

2 pivots

4 screw(M3)

2 tang .

4 washer

Tool

To fold a vise, hammer, blade+washer thickness steel place,

To cut hack saw, band saw, angle grinder

To grind file, sandpaper, angle grinder, belt sander, backstand.

To heat treat Blow torch, torch, forge, heat treatment oven, oil or water

To fold the steel, you put the plate in the vise to the folded highness you want. You put the two plier wrench , you fold to more than 90°, after you press the plate in the vise. You use the hammer (on an anvil or something strong) on the U you obtain in order to straighten it with the thickness plate in the u

After the folding

To the angle grinder i cut the place where the blade will go. more or less 2 cm deep.

Steel plate, ink, some draw....

After some bandsaw work.

It's shaped.

i clean the part i cut with the angle grinder.

I draw the middle of the blade

The scale are in position

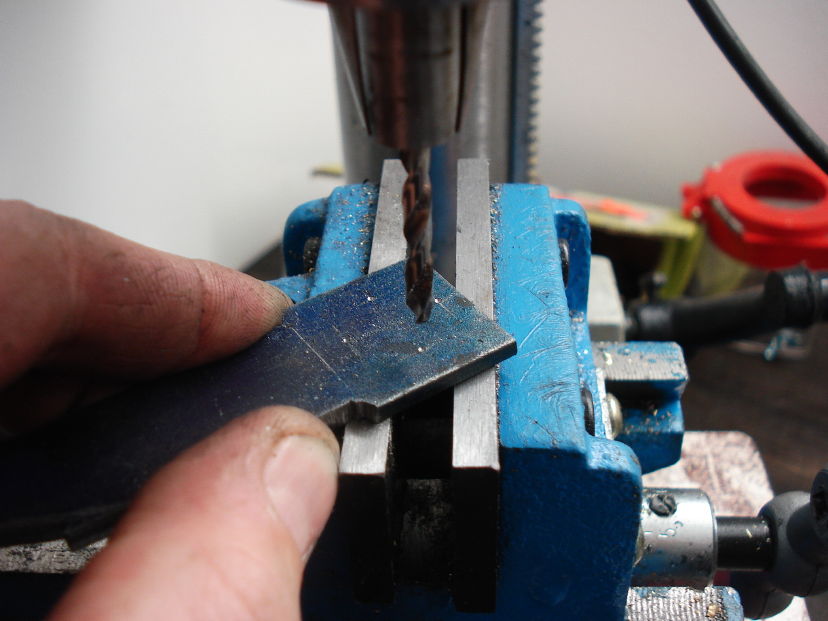

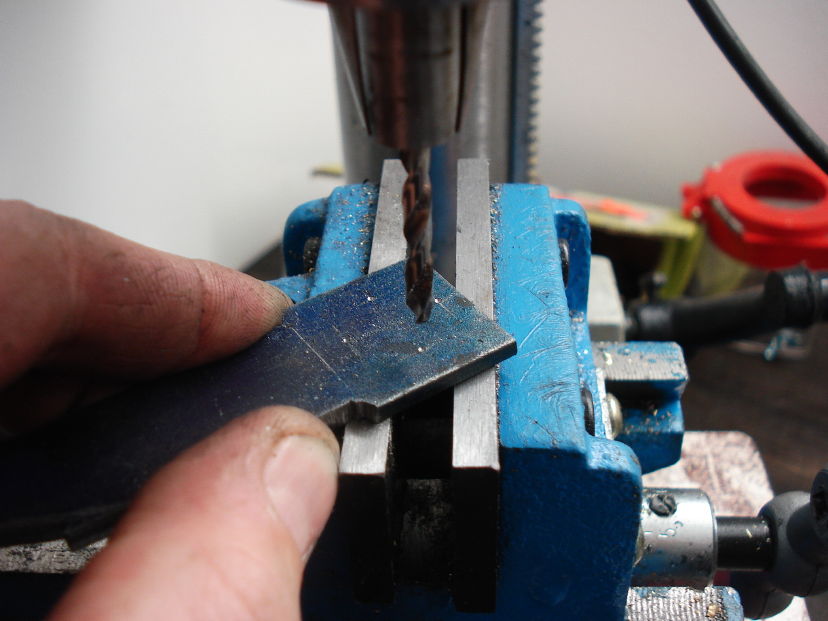

I point the futurs holes.

3.8mm

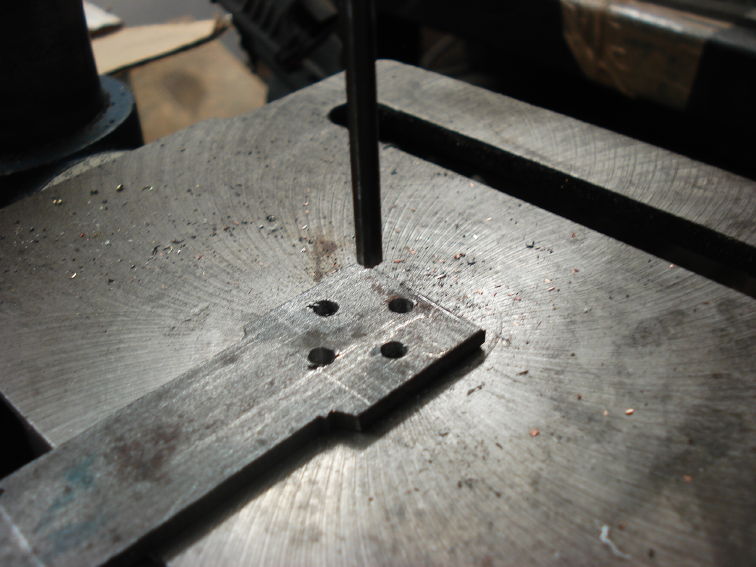

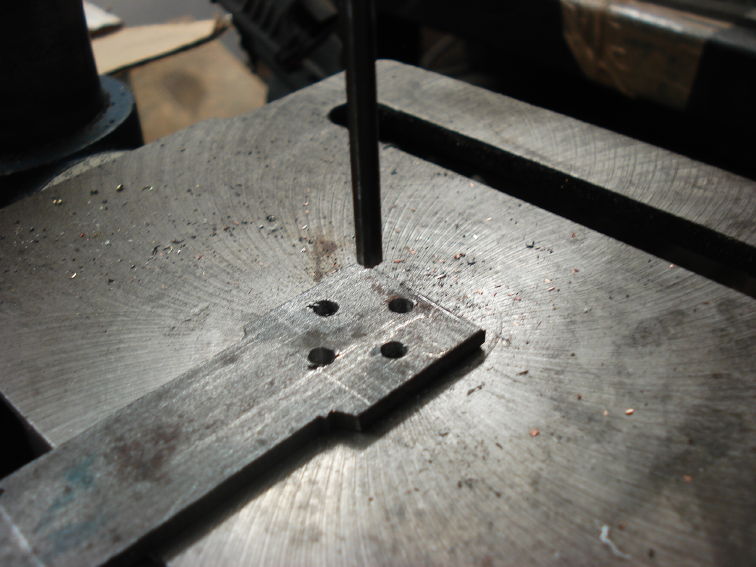

I reamed to 4mm the pivot, the tang place stayed to 3.8mm

Drilled and reamed

I point the futurs holes in the handle.

3,8mm

Reamed to 4mm

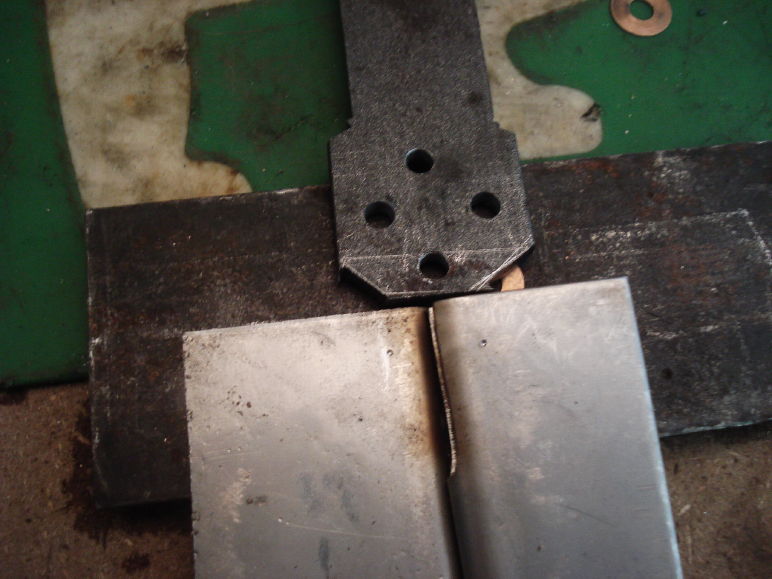

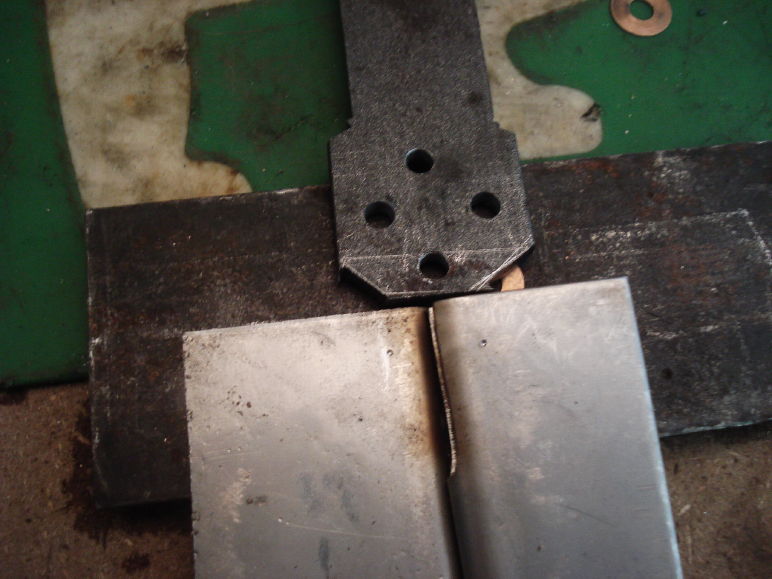

I build it in order to see where i have to not grind around the pivo

Draw of the futur handle.

I cut with the bandwaw.

It begin to seem to be a balisong

Open

I shaped a bit with a 60 grit belt.

I did the choild with dremel rotary burr.

Cleaned everything with 240 belt

My grind plied, (simply O1 hardened pieces with a stainless piece and two rolled pins.)

60grit

120 grit

It's thin before HT

Lazy fileworked

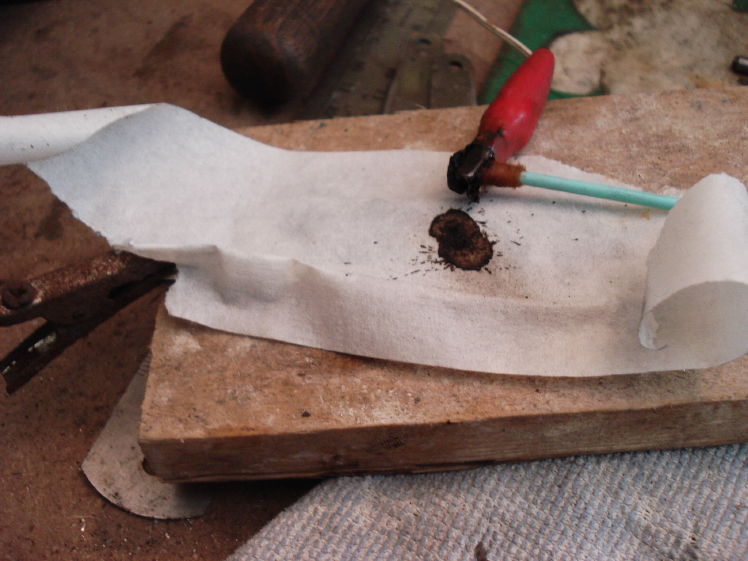

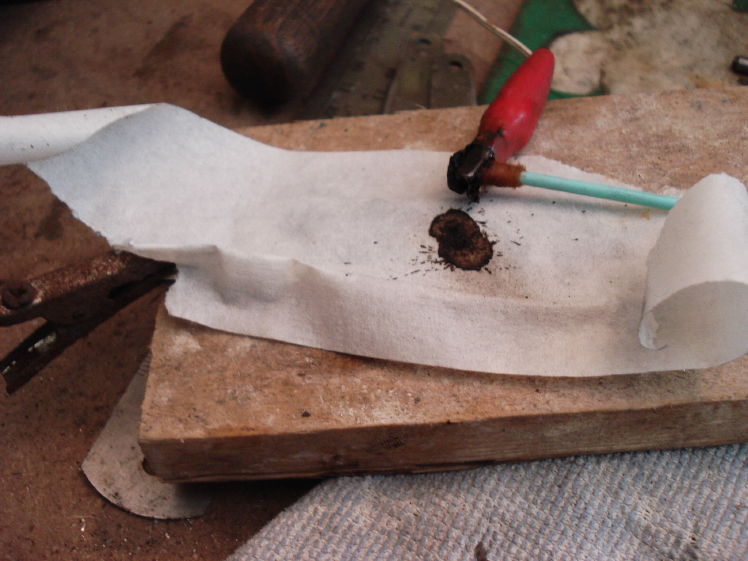

Propan torch oil hardening

Hardened and degreased. (to not too much dirt my belt)

The grind is white in order to see the color during the flash tempering

Flash tempering, the point is a bit darker, but it was 4mm too long, the point had been decreased after to go in the handle . And i temperered generally a bit more the point of the balisong.)

. And i temperered generally a bit more the point of the balisong.)

240 grit

500 grit

My poor stencil.

Electro etching

I decreased a bit the diameter of the tang in 100c6 hardened.

Everythin is on the spot, at the right size and polished.

Tang cup with the rotary burr.

Open

I cut the screw and polished the cut.

The pivot are decreased to the right size.

Polishing.

15 parts

500 grit to create the edge, some buffer to complete the work.

You have a small balisong not too much "bling bling". the aim is to use the same idea of the folded handle that i use to my Cardo No Kami.

It's thin, and cool to flip even if it's a bit short and thin to offer all the possibilty of a full size balisong.

9cm closed, , 3,2 cm widht, 7mm and 1cm to the thickest, open 15,3 cm, 6 cm sharp. XC75 blade full hardened, gold flash tempered. Hardened tang pins. 74g.

Material

steel for blade

stainless steel plate

2 pivots

4 screw(M3)

2 tang .

4 washer

Tool

To fold a vise, hammer, blade+washer thickness steel place,

To cut hack saw, band saw, angle grinder

To grind file, sandpaper, angle grinder, belt sander, backstand.

To heat treat Blow torch, torch, forge, heat treatment oven, oil or water

To fold the steel, you put the plate in the vise to the folded highness you want. You put the two plier wrench , you fold to more than 90°, after you press the plate in the vise. You use the hammer (on an anvil or something strong) on the U you obtain in order to straighten it with the thickness plate in the u

After the folding

To the angle grinder i cut the place where the blade will go. more or less 2 cm deep.

Steel plate, ink, some draw....

After some bandsaw work.

It's shaped.

i clean the part i cut with the angle grinder.

I draw the middle of the blade

The scale are in position

I point the futurs holes.

3.8mm

I reamed to 4mm the pivot, the tang place stayed to 3.8mm

Drilled and reamed

I point the futurs holes in the handle.

3,8mm

Reamed to 4mm

I build it in order to see where i have to not grind around the pivo

Draw of the futur handle.

I cut with the bandwaw.

It begin to seem to be a balisong

Open

I shaped a bit with a 60 grit belt.

I did the choild with dremel rotary burr.

Cleaned everything with 240 belt

My grind plied, (simply O1 hardened pieces with a stainless piece and two rolled pins.)

60grit

120 grit

It's thin before HT

Lazy fileworked

Propan torch oil hardening

Hardened and degreased. (to not too much dirt my belt)

The grind is white in order to see the color during the flash tempering

Flash tempering, the point is a bit darker, but it was 4mm too long, the point had been decreased after to go in the handle

240 grit

500 grit

My poor stencil.

Electro etching

I decreased a bit the diameter of the tang in 100c6 hardened.

Everythin is on the spot, at the right size and polished.

Tang cup with the rotary burr.

Open

I cut the screw and polished the cut.

The pivot are decreased to the right size.

Polishing.

15 parts

500 grit to create the edge, some buffer to complete the work.

You have a small balisong not too much "bling bling". the aim is to use the same idea of the folded handle that i use to my Cardo No Kami.

It's thin, and cool to flip even if it's a bit short and thin to offer all the possibilty of a full size balisong.

9cm closed, , 3,2 cm widht, 7mm and 1cm to the thickest, open 15,3 cm, 6 cm sharp. XC75 blade full hardened, gold flash tempered. Hardened tang pins. 74g.