C Craft

Well-Known Member

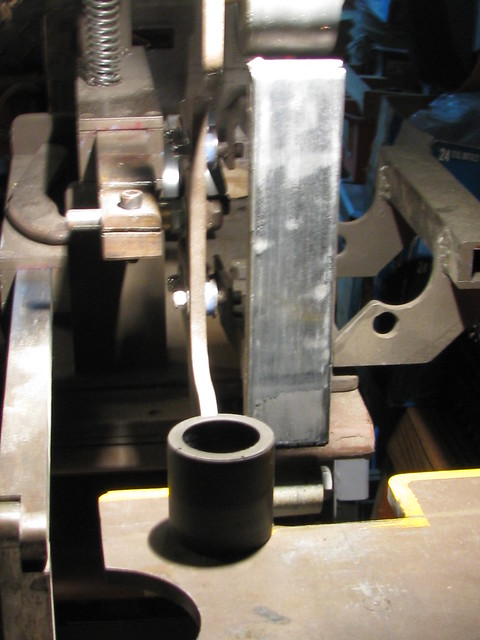

I got one I built and till today it was fairly quite for a step pulley with an adjustable belt! However today I was grinding something and as the grinder winds down I hear this tick, tick. noise!

So pulled the belt and put on a new one. Still hear it! Stopped and pulled the new belt and put the old belt back on. Still hear the tick tick and now it is getting louder. So I don't think it is the belt but, checked the seam and it appears OK!

I am beginning to think it may be a Square Flanged Mounted Bearings

I also am beginning to see a wear pattern on the left side of the drive wheel! That is another thing that has me thinking the bearing be going. It appears that the shaft may be slightly forward and thus turning the drive wheel juuuuuust enough, that it is putting more pressure on one side of that drive wheel!!

So has anyone else had one of these bearings go?? What did it sound like when it started. The more I run this one like this the louder the tick tick is getting and it also appears now to be getting a vibration. Anyone got any thoughts on these questions??

So pulled the belt and put on a new one. Still hear it! Stopped and pulled the new belt and put the old belt back on. Still hear the tick tick and now it is getting louder. So I don't think it is the belt but, checked the seam and it appears OK!

I am beginning to think it may be a Square Flanged Mounted Bearings

I also am beginning to see a wear pattern on the left side of the drive wheel! That is another thing that has me thinking the bearing be going. It appears that the shaft may be slightly forward and thus turning the drive wheel juuuuuust enough, that it is putting more pressure on one side of that drive wheel!!

So has anyone else had one of these bearings go?? What did it sound like when it started. The more I run this one like this the louder the tick tick is getting and it also appears now to be getting a vibration. Anyone got any thoughts on these questions??

2-2-2018 004

2-2-2018 004 8-20-16 005

8-20-16 005

2-2-2018 002

2-2-2018 002