How does the Lazer effect the edges that have been cut does it harden them or anything?

Update on my laser cut parts. For the last couple of days I've been deciding what I've got with the laser cut parts. Yes, Justin, it does harden the edges, big time. You can't file them or cut them on the bandsaw without first grinding the heat affected zone (HAZ) material off. For example, my hunting knife pattern will have the entire perimeter ground.The lightning holes and pin holes are fine as is. So, no problems with this pattern at all.

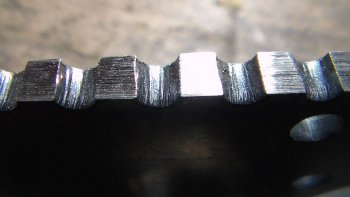

Now, my survival knife, that's another story. I drew all my jimping notches on my cad drawing, 10 in all. File won't touch them. Here's a close-up of one of the fresh blank's problem areas.

Since these are paracord wrapped all the edges have to be rounded. If someone was in an emergency situation and needed to unwrap the cord, I want these blades to still be comfortable to use. I also don't want any sharp edges that might damage the paracord over time. The holes also have to have a smooth chamfer on them for same reason. The HAZ was totally screwing this up. I started thinking I had made a mistake with the laser.

But, Evenheat to the rescue! I just got my new oven Friday and decided to try annealing the blanks. I made a 2 step program, ramping up to 1475 and then to 1200 at 50 deg per hour. I just tried one blank by itself first as a test and it was successfully softened, except I got a lot of scale on it. Then I tried 6 blanks in a SS pouch. Worked great!

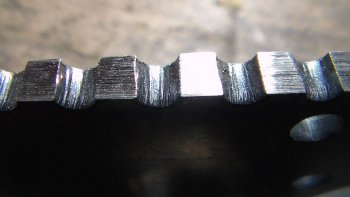

This allowed me to round all the edges and give all my jimping the touch I like. I like the way the notches look if you round the bottoms of them. Here you can see the before and after.

So, results? I have used a hardened blank as a jimping file guide in the past and it was pretty quick to file them that way. But, I would still be left with chamfering all the holes and rounding the internal edges. Even with the added annealing step, I think I'm still way ahead on money. SS foil isn't cheap, but I can wrap 6-10 at a time for $1.60 and the oven runs it's program automatically.

What do you guys think? Do you guys see any issues with annealing them? Even with the extra step, I'm still at half the price of water jet.