Hey y'all,

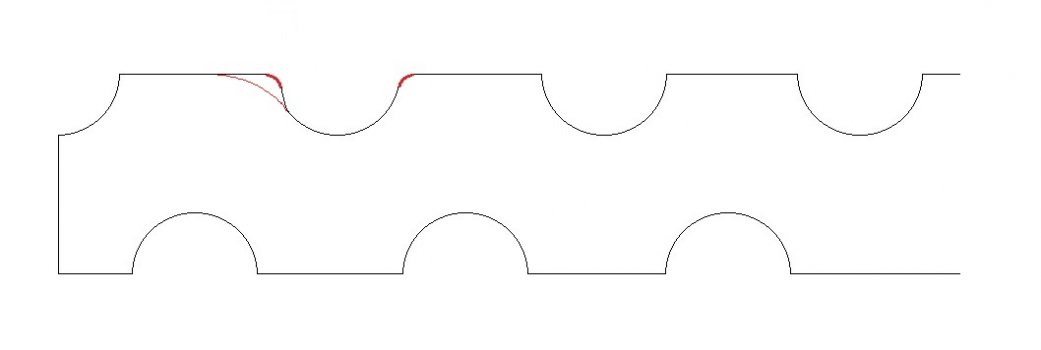

I just forged a billet starting with 21 layers of 1095 & 15n20. I forged that out then cut into 4 pieces, restacked, and forge welded. It is currently about 8"long, 2"wide, and close to a 1/2" thick. I was thinking about squaring it and trying to do some W's but I'm not sure if I already have to many layers. I see that others have started with around 15 layers squares that and forge out the W' s then cut, restacked, and welded for higher layer count.

For some reason I was wanting something besides raindrop, or plain ladder pattern but not sure what else I can do from here.

What do y'all think I should make from it at this point? Any suggestions?

Thanks

I just forged a billet starting with 21 layers of 1095 & 15n20. I forged that out then cut into 4 pieces, restacked, and forge welded. It is currently about 8"long, 2"wide, and close to a 1/2" thick. I was thinking about squaring it and trying to do some W's but I'm not sure if I already have to many layers. I see that others have started with around 15 layers squares that and forge out the W' s then cut, restacked, and welded for higher layer count.

For some reason I was wanting something besides raindrop, or plain ladder pattern but not sure what else I can do from here.

What do y'all think I should make from it at this point? Any suggestions?

Thanks