You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's going on in your shop?

- Thread starter Justin Presson

- Start date

Finished up the Damascus Hunter

Nice all the way around.

Randy Lucius

Well-Known Member

Bruce McLeish

Well-Known Member

You are just aworkin' y'alls fingers to the bone and lookin mighty fine while you're doin it ! Great job.

Heikki

KNIFE MAKER

I really like that steak knife profile in the middle. Looking forward to seeing it finished.Got three ready for heat treat. AEB-L. My first in stainless steel. Left and right are hunters. The middle one is an .080 steak knife. Planning on doing a plunge less grind. That will be another "first" too.

View attachment 67960

Daniel Macina

Well-Known Member

Sean Jones

Well-Known Member

Nice find Daniel. I could use a bigger vise myself.

Bruce McLeish

Well-Known Member

Only one thing to say .... Where's the wire brush and WD40 ?!!!!

Just how in the world did you do that? Is that what Boss called "stipple"? Almost looks like CruForge V bonded to the 4140 with the Nickel?Was experimenting with some different lamination stuff. This is not San Mai. You can probably tell since it continues through the tang. Little hidden tang neck knife. Just gotta do the guard and handle now.

Edit: CruForge V at the edge. 4140 towards the spine with a piece of nickel in between.

View attachment 67775

Daniel Macina

Well-Known Member

Only one thing to say .... Where's the wire brush and WD40 ?!!!!

Got the wire brush but the wd-40 will gum everything up. (Ask me how I know

Daniel Macina

Well-Known Member

Smallshop

KNIFE MAKER

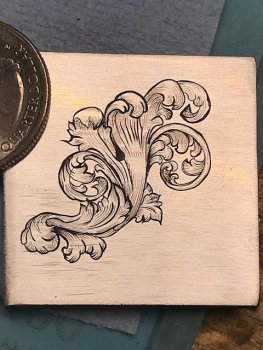

Tracy...beautiful work!! That looks real clean!continuing my engraving practice.

all shaded, now on to practice some in lay.

View attachment 67959

Half shaded

View attachment 67958

major lines have been cut twice, some shading in place.

View attachment 67957

Von Gruff

KNIFE MAKER

So you got the easy part done huhPre heat treat pic. These were heat treated last weekend. Working on final grinds now. Hopefully get to drilling and glue up this weekend.

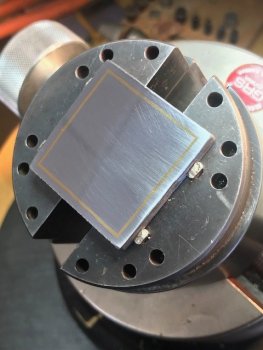

I have been concentrating on engraving practice for the last several weeks. After practicing in-lay with .999% silver (it is nearly as malleable as pure gold and a bit cheaper to practice with) I am now trying some gold in lay. This is about 2 bucks worth so it's not breaking the bank. There will be about 4" total in-lay and that will be around $12 which is cheaper than most mosaic pins for handles so it's maybe not as expensive as you might think. It does take an unreal amount of time though.

Here I am using 22kt gold. I meant to get 24kt as it more malleable but ordered the 22kt by mistake. Live and learn. It's a bit harder but with some effort it works. Cutting two straight parallel lines is the hardest part - at least for me. The channel has to be dug out then little divots in the center of the channel and slight under cuts along the entire edge are added. This holds the gold in place with a mechanical lock as it is hammered it into place using a brass punch in my pneumatic engraving tool.

Here I have stoned it down to 1000 grit with an EDM stone. You have to use plenty of oil while stoning. Despite the oil, the stone still loads up and stops cutting so a quick pass on some 120 grit sand paper opens the stone back up. It's tedious. I didn't realize cleaning up the in-lay would take more time than doing the actual in-lay. This took a couple days to cut the 4" square channel and in-lay one side of it. I expect it will go much quicker with practice but it is a slow process. This pic is zoomed in. With out magnification, the border is fairly straight but could still use some more clean up. Since this is practice, I wanted a quick peak to see my process was working. Now to go fill in the other 3". See you in a few days.

Here I am using 22kt gold. I meant to get 24kt as it more malleable but ordered the 22kt by mistake. Live and learn. It's a bit harder but with some effort it works. Cutting two straight parallel lines is the hardest part - at least for me. The channel has to be dug out then little divots in the center of the channel and slight under cuts along the entire edge are added. This holds the gold in place with a mechanical lock as it is hammered it into place using a brass punch in my pneumatic engraving tool.

Here I have stoned it down to 1000 grit with an EDM stone. You have to use plenty of oil while stoning. Despite the oil, the stone still loads up and stops cutting so a quick pass on some 120 grit sand paper opens the stone back up. It's tedious. I didn't realize cleaning up the in-lay would take more time than doing the actual in-lay. This took a couple days to cut the 4" square channel and in-lay one side of it. I expect it will go much quicker with practice but it is a slow process. This pic is zoomed in. With out magnification, the border is fairly straight but could still use some more clean up. Since this is practice, I wanted a quick peak to see my process was working. Now to go fill in the other 3". See you in a few days.

Dennis Morland

KNIFE MAKER

Bossdog-Check our Alec Steele on YouTube. He put together a bunch of stuff on gold inlays and engraving. Right up your alley.

Randy Lucius

Well-Known Member

Good looking batch of knives! I really like the profile on #78. Be sure to post the finished knives. Thanks!!Pre heat treat pic. These were heat treated last weekend. Working on final grinds now. Hopefully get to drilling and glue up this weekend.