You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's going on in your shop?

- Thread starter Justin Presson

- Start date

chrisstaniar

Well-Known Member

Was shaping a handle on the OSS and must have got the mosaic pins too hot... The internals started sliding out. Grrrrrr....#@$@#! Don't do that.

Super glue it and call it a practice knife I guess.

You can fix the mosaics as long as they aren't broken. Put them back in the tube, mix up some epoxy, color it (lots of choices), then put a piece of tape over one end of the pin and fill from the other side. It will be slow going.

If you happen to have a brake bleeder kit you can use the vacuum to slurp the epoxy into the tube, then tape off both ends and let it cure. When I make mosaics that's how I make the whole tube. It does the best job of avoiding any air pockets. That won't matter as much in this case as the pins are already in the knife.

Gene Kimmi

KNIFE MAKER

mike miller

KNIFE MAKER

That maple on the boner is pretty!

chrisstaniar

Well-Known Member

Ow, yeah all that hand stitching makes my fingers hurt just thinking about it. I like the maple burl as well it always looks great on a handle.

chrisstaniar

Well-Known Member

Daniel Macina

Well-Known Member

Bruce McLeish

Well-Known Member

Been doin some filing. Still got one on the file jig. Think I melted some files! BTW, here's a tip : if you are hand filing and keep getting shards of metal caught in the file teeth and then get the subsequent galling on your blade, stop and clean your file real well, then run it over a chalk source. Sheetrock works fine. once the teeth are covered with chalk, file away. No more galling of your blade.

Hey, John Wilson....recognize anything of your design ?

Hey, John Wilson....recognize anything of your design ?

Last edited:

Heikki

KNIFE MAKER

Nice! Looks like you could give Gene a run for his money.Been doin some filing. Still got one on the file jig. Think I melted some files! BTW, here's a tip : if you are hand filing and keep getting shards of metal caught in the file teeth and then get the subsequent galling on your blade, stop and clean your file real well, then run it over a chalk source. Sheetrock works fine. once the teeth are covered with chalk, file away. No more galling of your blade.View attachment 77415

Hey, John Wilson....recognize anything of your design ?

Bruce McLeish

Well-Known Member

That's who I was trying to emulate. But he uses power tools .... And youth!!!

tkroenlein

Well-Known Member

He's got more than power tools and youth going for him. I think he calls for a box truck to haul knives away on Fridays.That's who I was trying to emulate. But he uses power tools .... And youth!!!

Bruce McLeish

Well-Known Member

ah ha, grasshopper...you speak the truth. perhaps this is why I cannot catch up to his prodigious output. I may have to tack a different tack rather than stay on this heading. I fear that I may be headed for the rocks !!!

Bruce McLeish

Well-Known Member

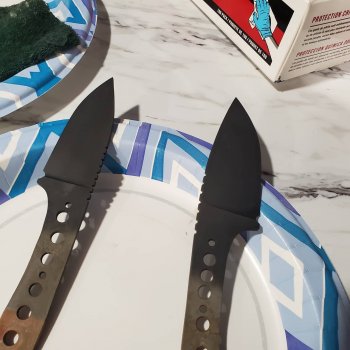

He wears three boots?Made a trio of boot knives for a friend, two are finished. 1084 with cedar elm/resin scales.

View attachment 77364

View attachment 77365

Randy Lucius

Well-Known Member

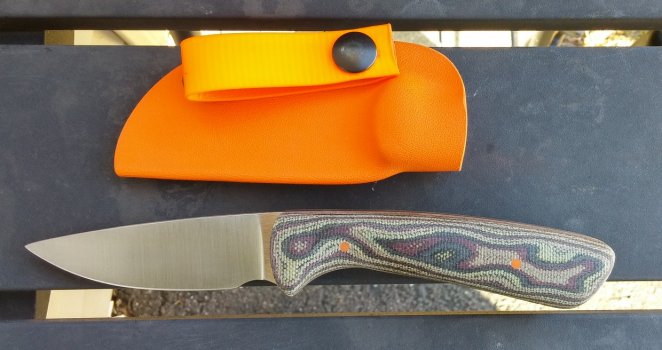

A couple of knives finished this week. The first one is a small skinner. Alabama Damascus with desert ironwood scales. Black liners and brass pins. Was made for an auction to help the family of a friend who recently passed.

The next one I'm kinda proud of. It's my first Chef's knife. I've had a lot of requests for kitchen knives so it looks like I will be making more of these. ABE-L stainless with maple and resin handle. Black liners with nickel silver pins.

The next one I'm kinda proud of. It's my first Chef's knife. I've had a lot of requests for kitchen knives so it looks like I will be making more of these. ABE-L stainless with maple and resin handle. Black liners with nickel silver pins.

Smallshop

KNIFE MAKER

Nice kitchen knife....but that handle! Amazing!A couple of knives finished this week. The first one is a small skinner. Alabama Damascus with desert ironwood scales. Black liners and brass pins. Was made for an auction to help the family of a friend who recently passed.

View attachment 77417

The next one I'm kinda proud of. It's my first Chef's knife. I've had a lot of requests for kitchen knives so it looks like I will be making more of these. ABE-L stainless with maple and resin handle. Black liners with nickel silver pins.

View attachment 77418

View attachment 77419

View attachment 77420