John T Wylie Jr.

Rockstar and ACE vBulletin troubleshooter

Awhile back a co-worker approached me about what to get her son for making Eagle Scout , and she was trying to decide to get him camping gear or a knife as a reward. I suggested she go with the camping gear.

That shocked her , since I am known as the knife nutt at work. Go figure 2thumbs

When she asked Why not a knife ? I informed her that he is getting a reward knife , only she ain't paying for it , then I asked her permission to make him one , which after showing her pictures of some of my past work as well as my carry knife , she readily agreed.

This is the simple design I came up with:

blade steel 154CM .140 thick (donated to the cause by Alpha Knife Supply)

blade length: 3.4"

heat treat: Paul Bos

The beginning , drawn on paper , then traced onto the steel , rough cut ( and I do mean ruff ) on the band saw , then final profile done on the Bader with 60 grit.

Here it is profiled , flat sanded poor boy style on the flat platen and also the 9" disc. Wasn't sure if I would taper the tang or not , so I drilled many holes just to be safe .

grinds done , jimping done on the spine with a 20LPI checkering fille , sand hand satin work done ( up to 220 ) and it was off to Paul Bos for HT.

Fast forward a little bit ( thats knifemaker time for 2 months ).

).

blade back from HT , hand satin to 400 grit ( sorry , that all the finer I have)

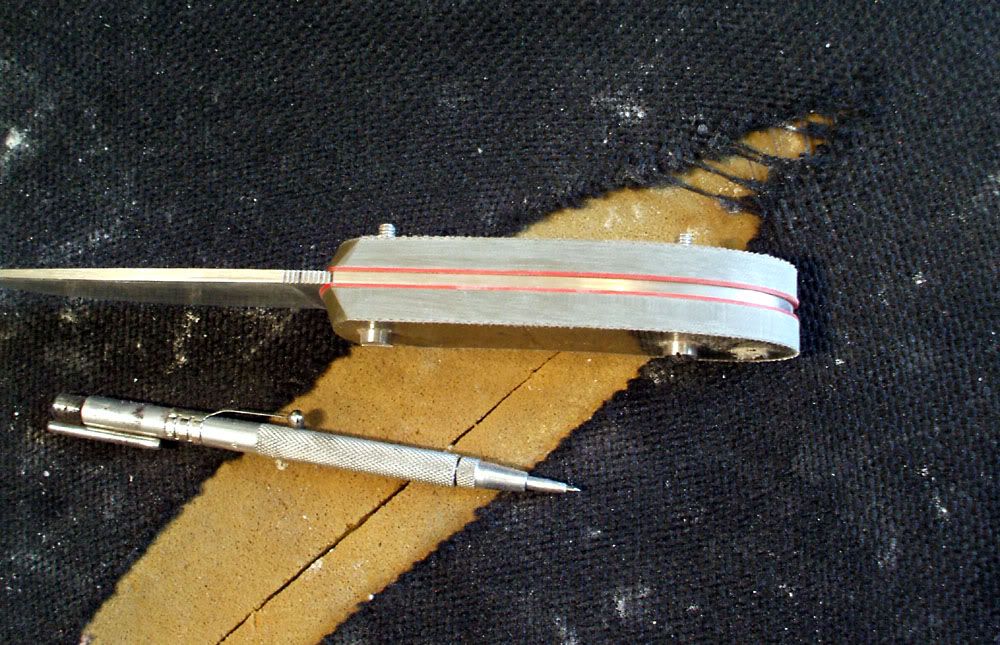

Start to work on adding the scales.

That shocked her , since I am known as the knife nutt at work. Go figure 2thumbs

When she asked Why not a knife ? I informed her that he is getting a reward knife , only she ain't paying for it , then I asked her permission to make him one , which after showing her pictures of some of my past work as well as my carry knife , she readily agreed.

This is the simple design I came up with:

blade steel 154CM .140 thick (donated to the cause by Alpha Knife Supply)

blade length: 3.4"

heat treat: Paul Bos

The beginning , drawn on paper , then traced onto the steel , rough cut ( and I do mean ruff ) on the band saw , then final profile done on the Bader with 60 grit.

Here it is profiled , flat sanded poor boy style on the flat platen and also the 9" disc. Wasn't sure if I would taper the tang or not , so I drilled many holes just to be safe .

grinds done , jimping done on the spine with a 20LPI checkering fille , sand hand satin work done ( up to 220 ) and it was off to Paul Bos for HT.

Fast forward a little bit ( thats knifemaker time for 2 months

blade back from HT , hand satin to 400 grit ( sorry , that all the finer I have)

Start to work on adding the scales.

Last edited: