Calvin Robinson

Moderator Christian Forum

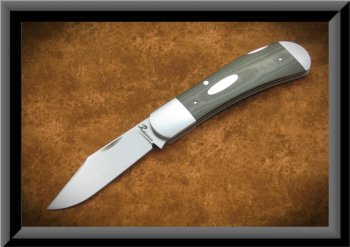

Friday morning I walked in to my shop,all I had to do this day was finish this folder from the 400 grit disk grinder finish to 800 grit hand finish then,buff,clean up,sharpen.

As I walked up to my work bench where this unfinished folder was laying,something on the floor caught my eye. To my horror I spied this bronze washer laying there,it's supposed to be inside the knife!

So I had to knock the pivot pin out,put the stray washer in its place then insert a new pin,peen and grind flush. The problem was,I couldn't see the pivot pin! I had hidden it so well I couldn't find it. A drop of ferric chloride quickly revealed the pin so I could center punch it,drill about half way through with a .059 drill bit and then drive the pin out. I made a G-10 wedge to spread the knive open just enough to insert the combination of blade and two washers in place. Saliva proved perfect to stick the perfectly flat washers to the perfectly flat blade tang. A long taper on one end of my new pin aligned everything perfectly as I pushed it through the holes in my bolster.

I thought I had already made every mistake there was to be made in folder making but I made a new one. I will now be more careful when assembling for the last time before peening and will check one last time before peening and then check again!

As you can see,everything worked out well in the end,thank God!

As I walked up to my work bench where this unfinished folder was laying,something on the floor caught my eye. To my horror I spied this bronze washer laying there,it's supposed to be inside the knife!

So I had to knock the pivot pin out,put the stray washer in its place then insert a new pin,peen and grind flush. The problem was,I couldn't see the pivot pin! I had hidden it so well I couldn't find it. A drop of ferric chloride quickly revealed the pin so I could center punch it,drill about half way through with a .059 drill bit and then drive the pin out. I made a G-10 wedge to spread the knive open just enough to insert the combination of blade and two washers in place. Saliva proved perfect to stick the perfectly flat washers to the perfectly flat blade tang. A long taper on one end of my new pin aligned everything perfectly as I pushed it through the holes in my bolster.

I thought I had already made every mistake there was to be made in folder making but I made a new one. I will now be more careful when assembling for the last time before peening and will check one last time before peening and then check again!

As you can see,everything worked out well in the end,thank God!