Thanks guys.

Rex- Go for it buddy. No copywrites here, LOL, feel free to make a clone if you want to.

I will say that although I've only messed with mine for few minutes it does function fine in this configuration.

That said- The water-cooling will certainly be worthwhile as this sucker builds heat QUICK ! Even with very little belt tension and grinding for a few seconds at a time it does build heat.

With my pathetic rate of production this will be workable BUT It will be SO worth it to build a stand alone attatchment on it's own tooling arm just as Brian has done. I have very little raw materials to build stuff out of at this point so I threw this together in a few minutes to play with.

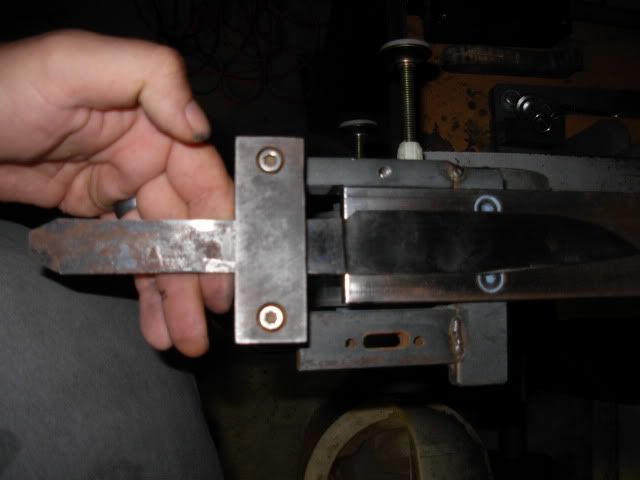

I just used a piece of 1/4" x 2" hot rolled 1095 to make the platen and would've preferred to make it wider so the mounting screws were on the outside of the belt.

Also I started with a 1/8" radius figuring I can experiment and make the radius bigger till I'm satisfied with the function and the look of my plunges

I haven't played with it enough to make a real report other than it does work and makes perfectly matching plunge radius.

I'm not going to be using this thing probably at all before the Bladeshow and had intended to swing by and talk with Brian and Kyle about it.

Joint lap seems like it may be an issue. Could be increased because of the extremely small radius I started with. Thinking that Norax belts may solve this issue though (?) I need to get a set for my surface grinder anyway so I'll be trying those out soon.

I found that running the belt TOWARDS me was the way it worked best as running it in reverse seemed like it wanted to pull the blade up onto the platen totally trashing that nice plunge line.

As far as getting used to it I really have only played on a couple blades that were pretty much finish ground without this platen in mind. I think grinding for use with this platen will shorten the learning curve consideably and don't see that as being a problem really. There will be a learning curve but I'm not anticipating it to be steep.

That's my take as of today reserving the right to change my opinions after using it some more

Take care fellas, Josh