Self Made Knives

Well-Known Member

Hey, guys, I've never made a kitchen knife of any sort, but after trying to butcher a deer the other day with my wife's assortment of kitchen knives, I want my own personal butcher knife. She can't use it, it'll be just for processing deer, or other large game.

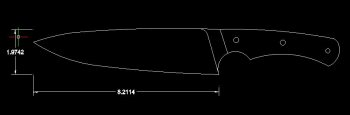

Here's a quick cad drawing I came up with, just tossing around design ideas. This is what seems like a chef knife to me, but maybe I should be thinking more of a deboning type? Please point me in the right direction as far as design improvements, I'm not a cook at all and don't know much at all about kitchen knives.

Would this design be ok for butchering deer? If not, what would? And lastly, any favorite steels for butchering? I'm thinking a stainless steel.

Here's a quick cad drawing I came up with, just tossing around design ideas. This is what seems like a chef knife to me, but maybe I should be thinking more of a deboning type? Please point me in the right direction as far as design improvements, I'm not a cook at all and don't know much at all about kitchen knives.

Would this design be ok for butchering deer? If not, what would? And lastly, any favorite steels for butchering? I'm thinking a stainless steel.