Ernie Swanson

SASSY PINK LUUNCHBOX KNIFE MAKER

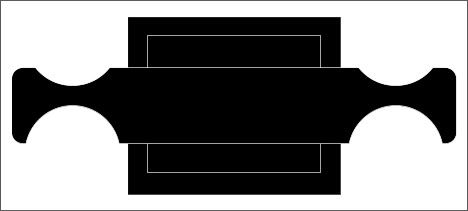

This is A flat grinding jig that I have been working on and finished it this morning. I had to also grind a blade to test it out.

I must say it works pretty darn good2thumbs

All you do it put a knife in it and set your angle by adjusting the wing nuts.

I ground one blade at about 4 degree angle from 90.

I glued leather to the inside of each clamping piece for a better hold.

Sorry for the crappy looking welds, my big welders speed knob broke and my helmet is at work!!

I must say it works pretty darn good2thumbs

All you do it put a knife in it and set your angle by adjusting the wing nuts.

I ground one blade at about 4 degree angle from 90.

I glued leather to the inside of each clamping piece for a better hold.

Sorry for the crappy looking welds, my big welders speed knob broke and my helmet is at work!!