EdCaffreyMS

"The Montana Bladesmith"

Been feeling a little better the last few days, and since I've not been at the forge in a while....I just couldn't stand it anymore. After chatting with Bing on Saturday morning, I had an idea........

I built a "can".....4"x4"x6".....plugged one end with a piece of 3/8" place, laid out a stack of 1080 & 15N20 diagonally. Filled the remaining space in with 1/4" W1 rods, then took up all the air space with 1095 powder, to which I added 10% nickel powder.

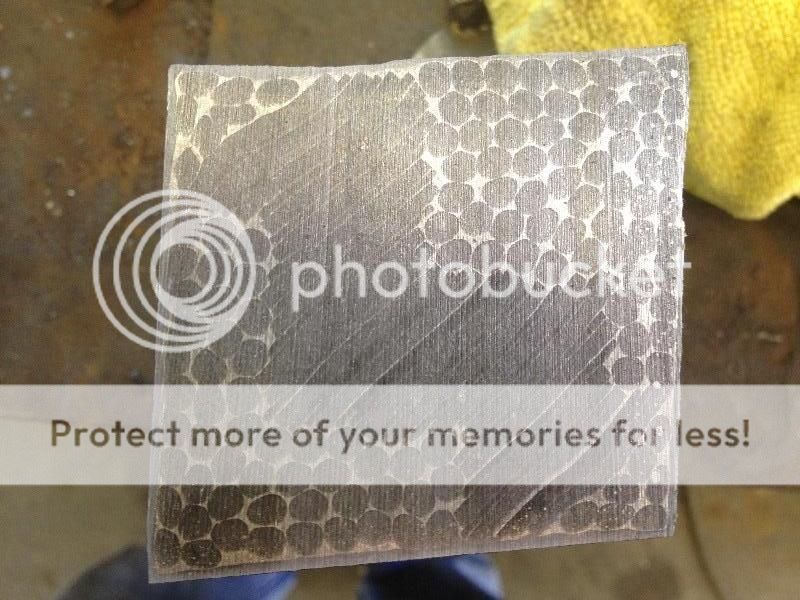

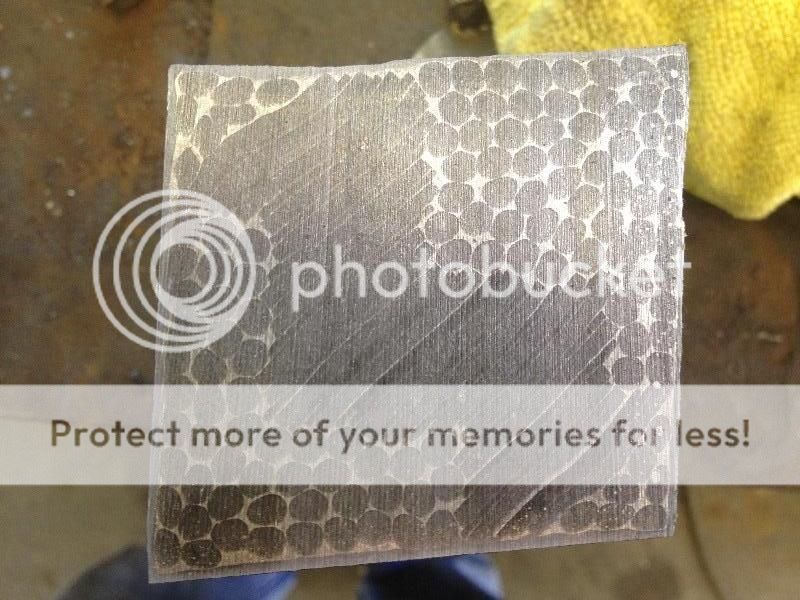

After about 45mins in the forge, this was how far I got..... 3"x3"x16".....then the forge lining failed on me. NUTS! Thankfully I had another welding forge ready to go that I spent the rest of the afternoon putting in place and setting up.

Got the replacement forge going, and the heat that I'm used to......

Worked the billet down just a bit more, let it cool, then because it was so large, I saw cut it in half, just so it would be easier to handle.

Next step is to forge the two halves down to about 1 1/2" square, anneal, and mill off the can, then cut each in half again. That will give me four pieces to decide how to orient and 4-way. Depending on what I come out with, it may go to an 8, or even a 16 way.

More to come.

I built a "can".....4"x4"x6".....plugged one end with a piece of 3/8" place, laid out a stack of 1080 & 15N20 diagonally. Filled the remaining space in with 1/4" W1 rods, then took up all the air space with 1095 powder, to which I added 10% nickel powder.

After about 45mins in the forge, this was how far I got..... 3"x3"x16".....then the forge lining failed on me. NUTS! Thankfully I had another welding forge ready to go that I spent the rest of the afternoon putting in place and setting up.

Got the replacement forge going, and the heat that I'm used to......

Worked the billet down just a bit more, let it cool, then because it was so large, I saw cut it in half, just so it would be easier to handle.

Next step is to forge the two halves down to about 1 1/2" square, anneal, and mill off the can, then cut each in half again. That will give me four pieces to decide how to orient and 4-way. Depending on what I come out with, it may go to an 8, or even a 16 way.

More to come.

Last edited: