Bruce Bump

Forum Owner-Moderator

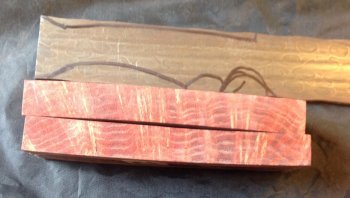

With a surface grinder you are only grinding a small amount with each pass. I think the scalloped belts are great for that as they don't have a sharp edge and blend well. Plus they were cheap as they are only 1" wide not many buyers on ebay. I'm always looking for 1 x 72" coarse belts. These scalloped belts are 100 grit and don't last long hogging it off like this. I went through 4 or 5 to make all this steel wool.

Bruce,

Any particular reason for a scalloped belt on the surface grinder ? I've always just used regular belts.

Thanks buddy,

-Josh