You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

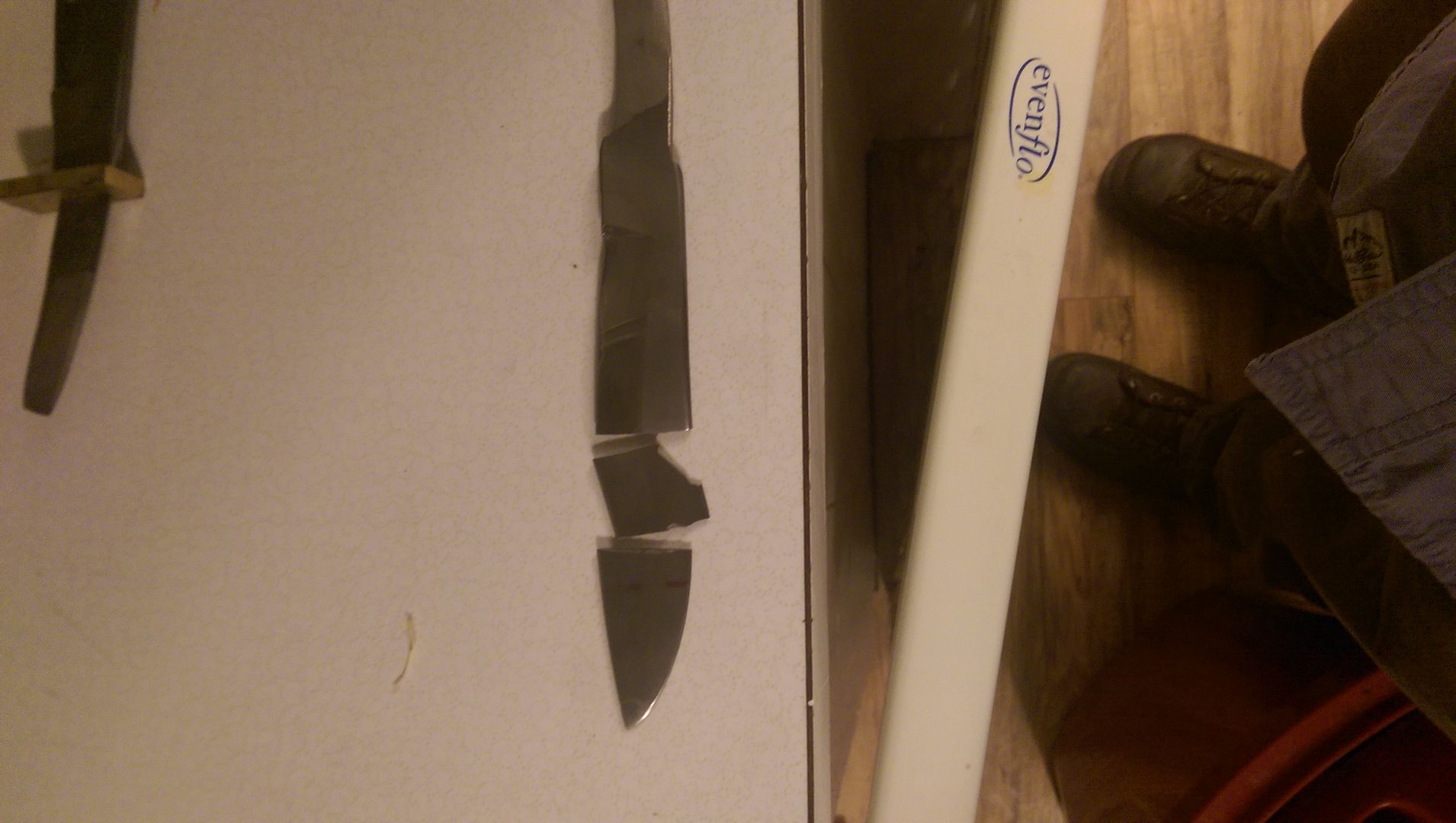

My first completed knife.

- Thread starter purequill

- Start date

ricky_arthur

Well-Known Member

Nevermind. Nice knife.

McClellan Made Blades

Well-Known Member

It is.....both? It's the second blade I forged, I have two others I am doing handles on right now and the other blade was tested to destruction. I am however not alone in my endeavors. I have a couple of pretty great mentors walking me through the process.

'PURE',

I'm not sure who your "mentors" are, but I am positive of where the inspiration comes from. Those are the spitting image of Ed Fowlers design, which is a great design for working knives, it looks like you have a skinner there that will service your cutting needs for a very long time!

Now were you shooting for a skinner/Hunter type blade or more of a utility type? or was it a combination of the 2? Either way, it turned out GREAT! If your edge flex passed a 1/4" rod, you should have a nice blade there, you said the last one(your first forged blade), was tested to destruction, how did it do on the 90* flex test? Just curious, I've not tested mine in that one yet, after all the work that god into one, I tend to get attached by the time I should be flexing it. As I do a lot of work by hand, its just my way, I'm getting better with my grinder, but play it safe and don't spend a lot of time grinding on the KMG, I will take it to my work bench and put the paper and files to it, so that I keep my success rate up !

You do have a winner here , and you are an excellent example of having a mentor to work WITH YOU CAN DO!! Keep it up, I hope to see a new design soon, Rex

Thanks very much BossDog! I appreciate everyones positive response and apologize for taking off on a tangent there for a bit. McClellan, I am working with Chris Amos and Ed occasionally. It was designed to be a skinner for sure, I will be posting up two more which are much smaller and meant for more of a utility vibe. I will post a picture of the first blade which was destroyed. It didn't pass but did do exactly as we expected. lol. I didn't adhere to the "forge it thick" rule and ended up with a pretty lithe blade. It made about 60 deg and snapped. We moved it deeper in the vise and had the same result.

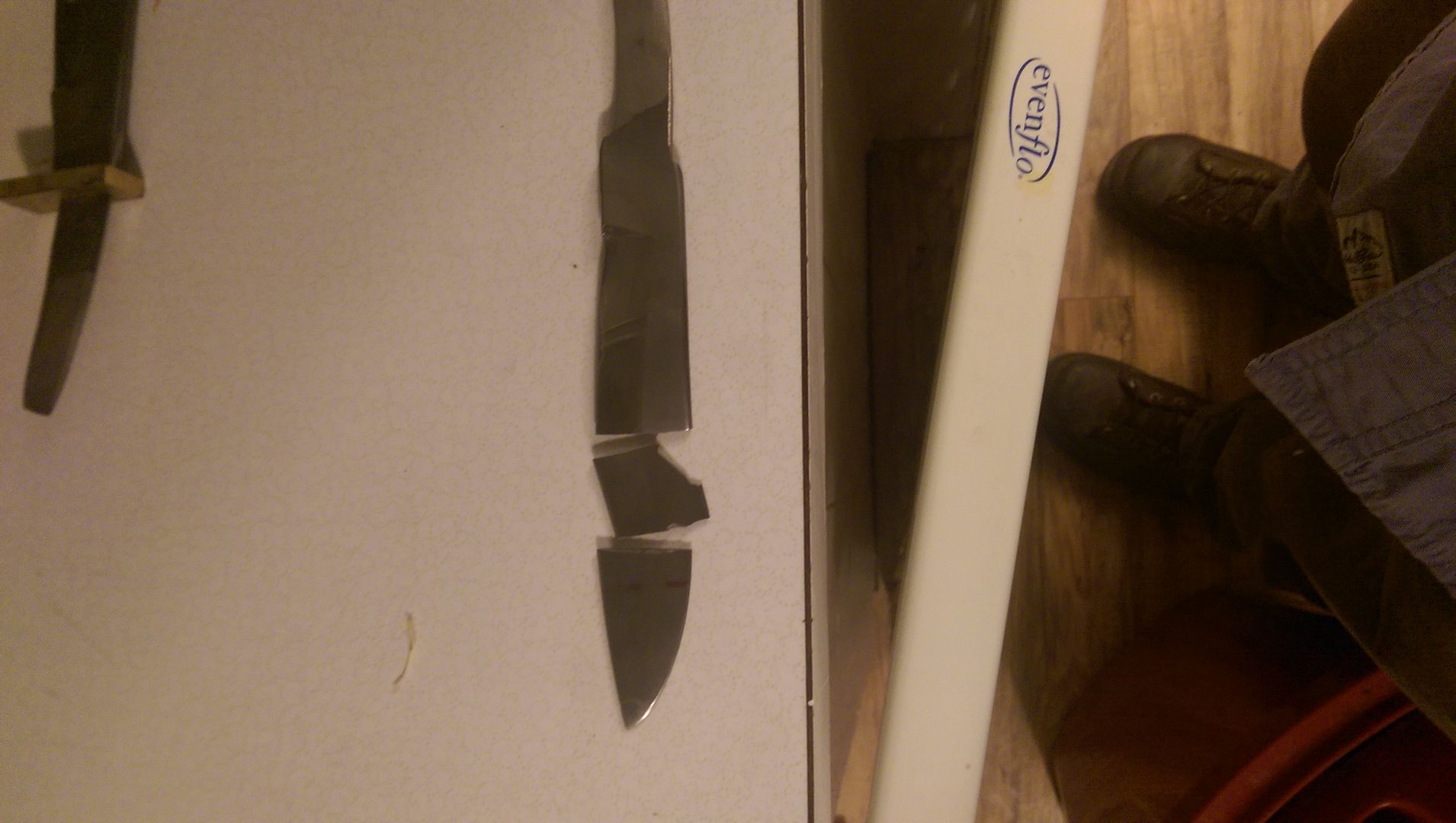

There she be. I'll be breaking alot more. haha.

There she be. I'll be breaking alot more. haha.

There she be. I'll be breaking alot more. haha.

There she be. I'll be breaking alot more. haha.

T

Tim Peterson

Guest

Great Knife!