Fellhoelter

Well-Known Member

I really used my converted surface grinder today.

I had played around with it a bit a couple of weeks ago, grinding a blade, but I got down to business tonight.

I have a 90 duro wheel, which seems plenty hard, and was able to take .010" off at a whack in annealed CPM154.

I've seen people say they get ten at a time with a belt, but never believed them.

Not for a second did I believe it.

I have hundreds, perhaps thousands of hours standing in front of a surface grinder as a toolmaker and thought "no way"

Switching to a belt was a hard thing for me to do, because as a machinist, it's just wrong.

Wrong I tell you.

But, here I am now, with a belt, taking off .010" in 1 pass, with almost zero heat build up !!

No heat !

I took 6 folder blades down .026" in 20 minutes, ending with an A45 gator belt.

that's a lot of metal, in not a lot of time.

I'm impressed, I can't wait to master this new system.

Never once did I feel in peril of throwing parts of the chuck.

There was no heat.

Parts are flat and parallel within 2 tenths.

These were things that concerned me...

.010" with a 60 grit belt @ 90 degrees to the cutting edge

flip, do the same on the other side.

Bam, .020" off in 7 or 8 minutes.

Lay parts so grind is now parallel to cutting edge, and take .002" off with an A45 Gator, then .001"

Flip, and do it again.

Done.

I still have .008 to go after heat treat, we'll see how it does on hardened stock.

All in all, unbelievable.

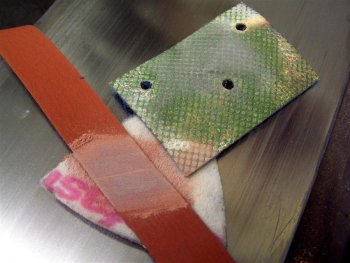

Edit : Adding a link to pictures.

Built a quick page on my site with some pics.

Picture here is a link to that page.

I had played around with it a bit a couple of weeks ago, grinding a blade, but I got down to business tonight.

I have a 90 duro wheel, which seems plenty hard, and was able to take .010" off at a whack in annealed CPM154.

I've seen people say they get ten at a time with a belt, but never believed them.

Not for a second did I believe it.

I have hundreds, perhaps thousands of hours standing in front of a surface grinder as a toolmaker and thought "no way"

Switching to a belt was a hard thing for me to do, because as a machinist, it's just wrong.

Wrong I tell you.

But, here I am now, with a belt, taking off .010" in 1 pass, with almost zero heat build up !!

No heat !

I took 6 folder blades down .026" in 20 minutes, ending with an A45 gator belt.

that's a lot of metal, in not a lot of time.

I'm impressed, I can't wait to master this new system.

Never once did I feel in peril of throwing parts of the chuck.

There was no heat.

Parts are flat and parallel within 2 tenths.

These were things that concerned me...

.010" with a 60 grit belt @ 90 degrees to the cutting edge

flip, do the same on the other side.

Bam, .020" off in 7 or 8 minutes.

Lay parts so grind is now parallel to cutting edge, and take .002" off with an A45 Gator, then .001"

Flip, and do it again.

Done.

I still have .008 to go after heat treat, we'll see how it does on hardened stock.

All in all, unbelievable.

Edit : Adding a link to pictures.

Built a quick page on my site with some pics.

Picture here is a link to that page.

Last edited: