You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Taking the dive into knife making

- Thread starter Mudman

- Start date

craigbladeworks

Well-Known Member

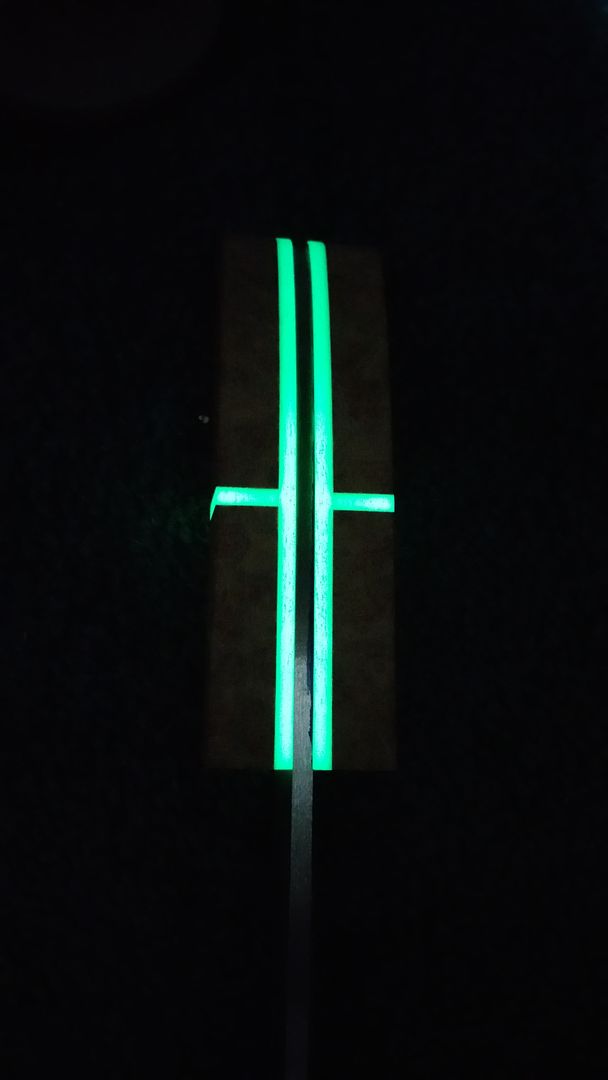

That moonglow looks fantastic.

Thank youThat moonglow looks fantastic.

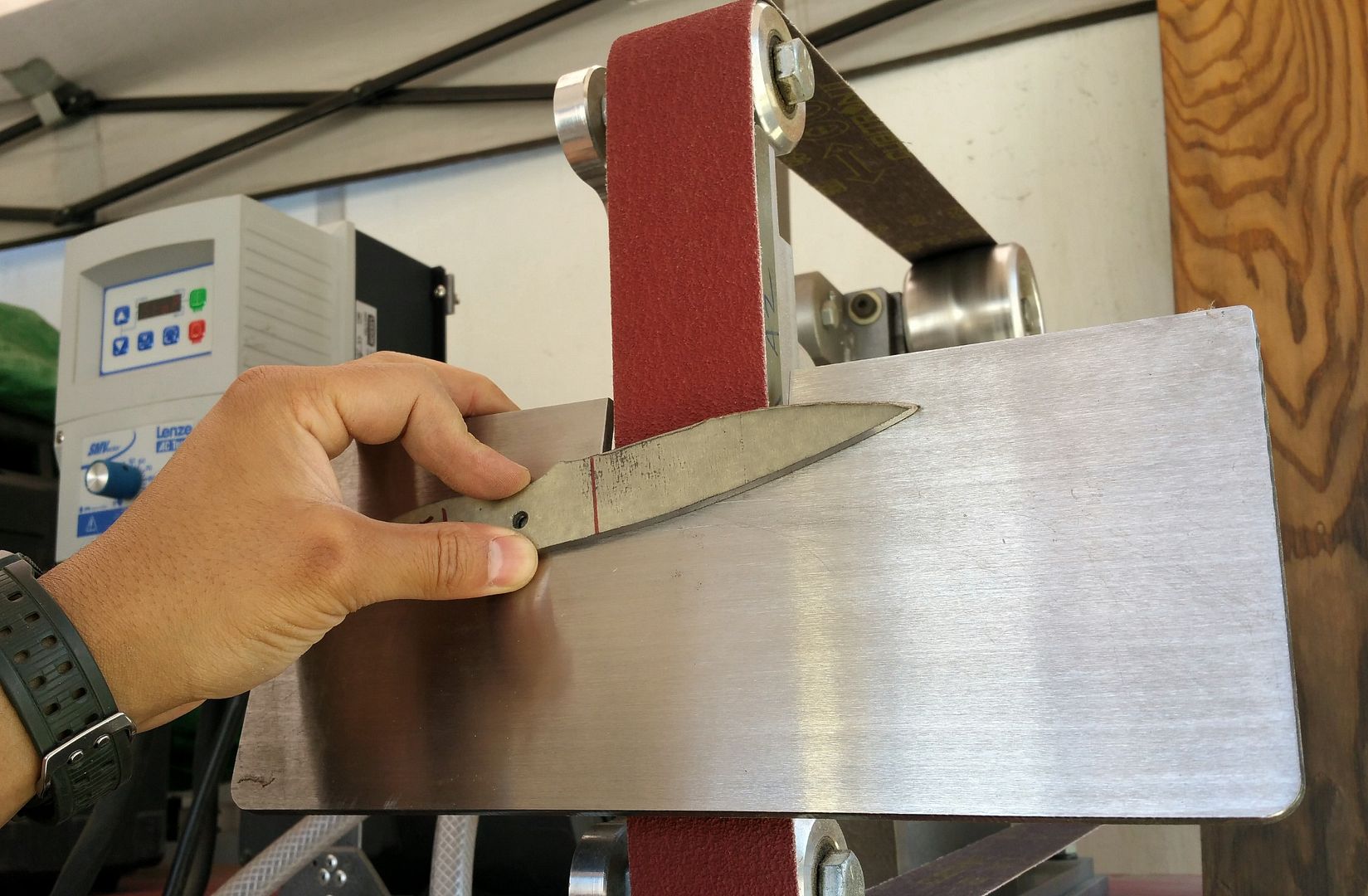

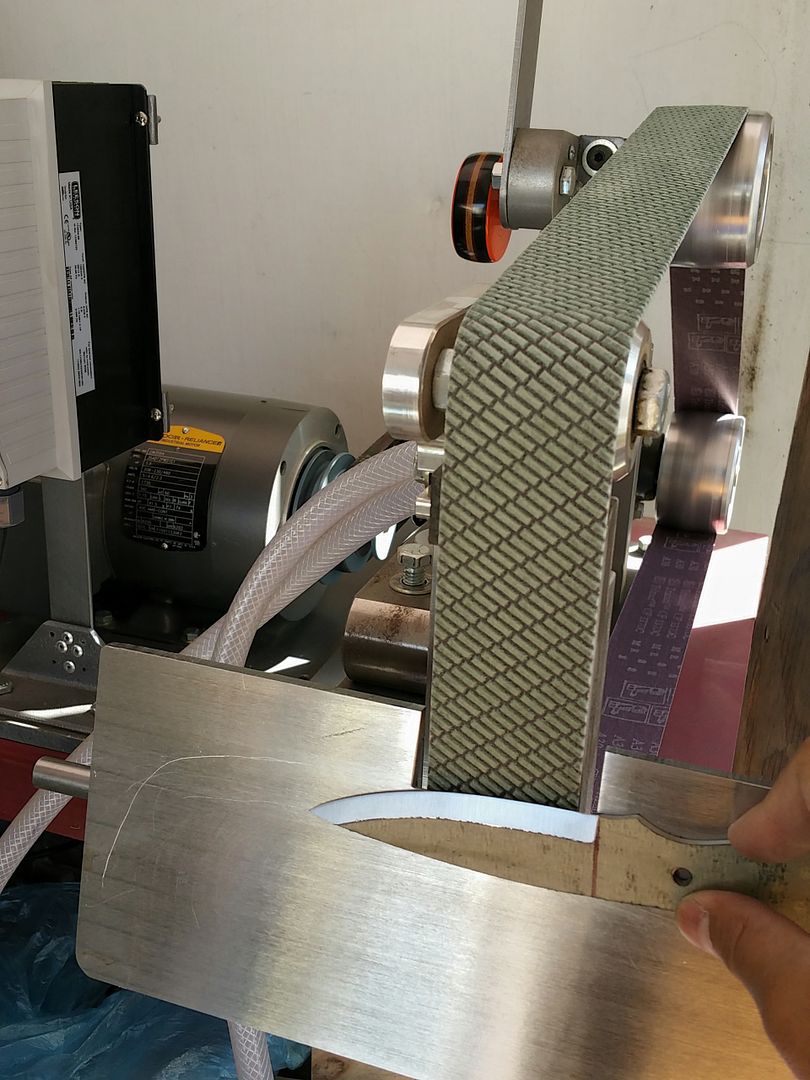

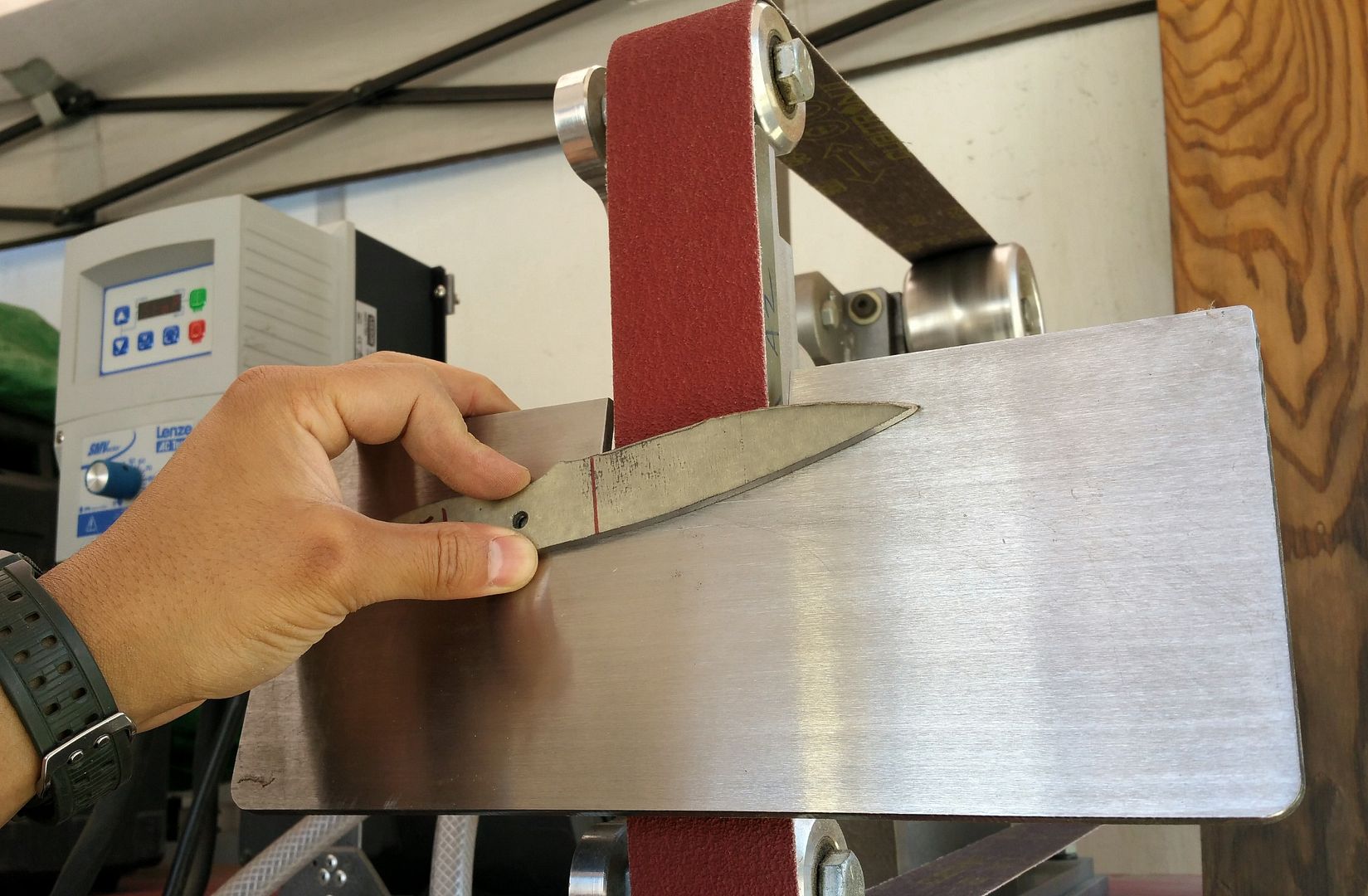

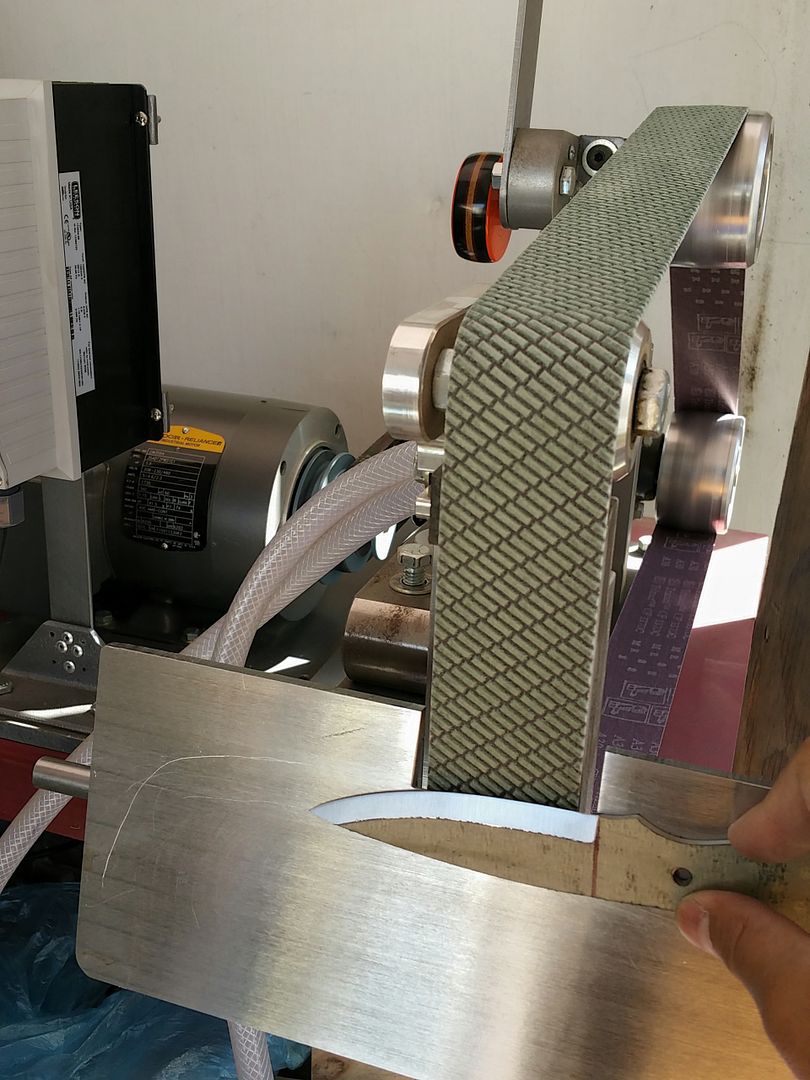

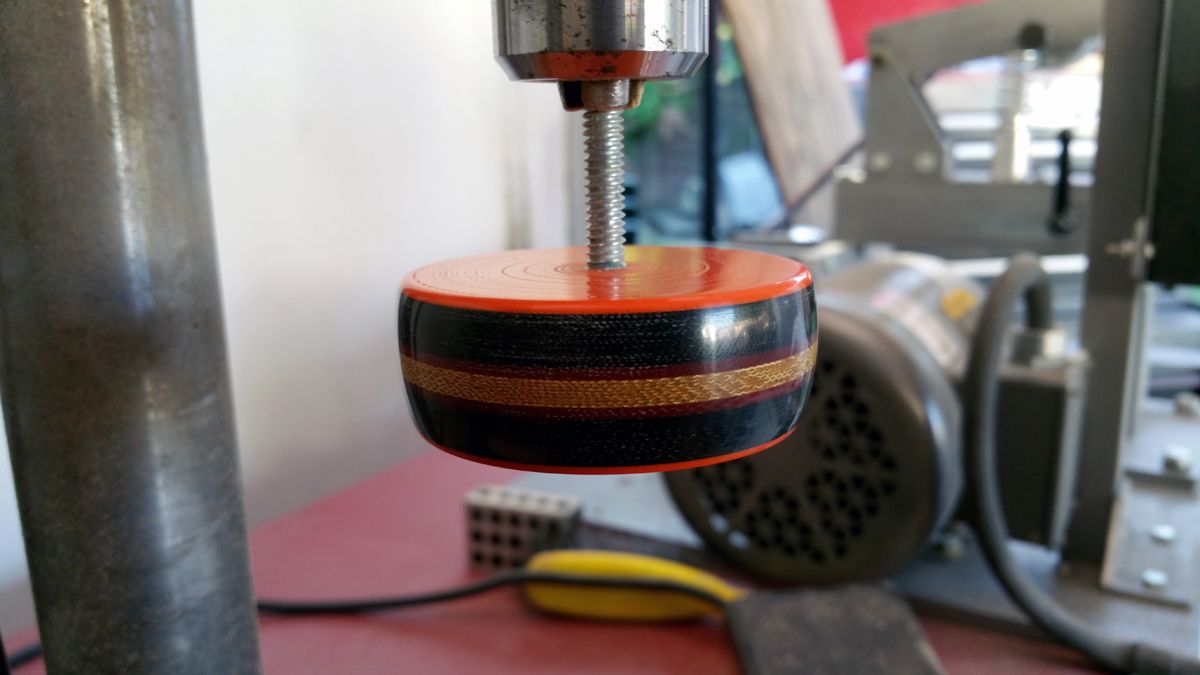

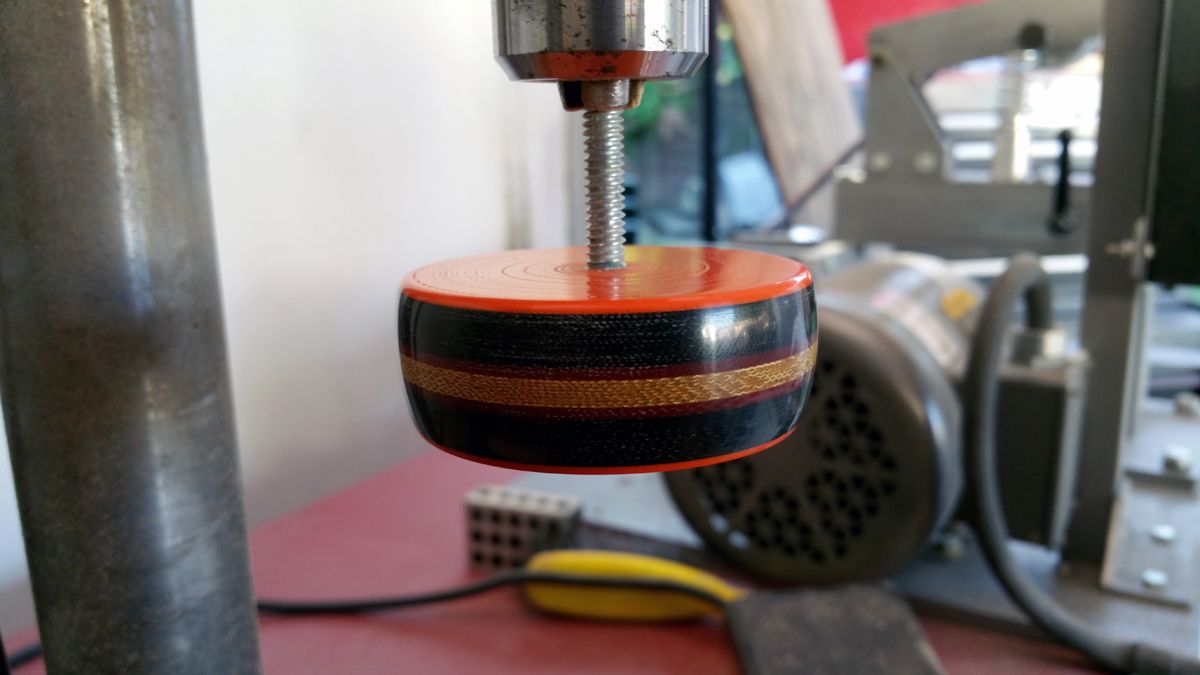

Got to sneak in a little grinding before heading out to work.

Love me some Gators

One of my weird steps, is doing the flats first, then taping and grinding in the edge. After I will hit it with a quick pass on the first grinder to get a crisp bevel transition, light hand finish and glue the handles.

Love me some Gators

One of my weird steps, is doing the flats first, then taping and grinding in the edge. After I will hit it with a quick pass on the first grinder to get a crisp bevel transition, light hand finish and glue the handles.

Spalted Big Leaf Maple Burl dyed Teal with red paper liner

Roughed out

Smoothed out facets on slack belt to 400 grit

Also made an upgrade to my safety gear after seeing a friend's. Had been wanting a full face, but didn't like the ones I saw prior to this one.

Replaced the old respirator and safety glasses with a full face

Hand sanded another blank for the next knife order.

Did a little warm up blade, before I get started on orders. This is a blade I botched a while back, and decided to keep it as a personal knife.

A2 Steel, Drewcarta handle with black liner. Sanded to 400grit then polished.

Left side of the handle at 400 grit via scalloped slack belt- right straight to the buffer

Finished

Current batch: Did a little more profiling to get it where I want.

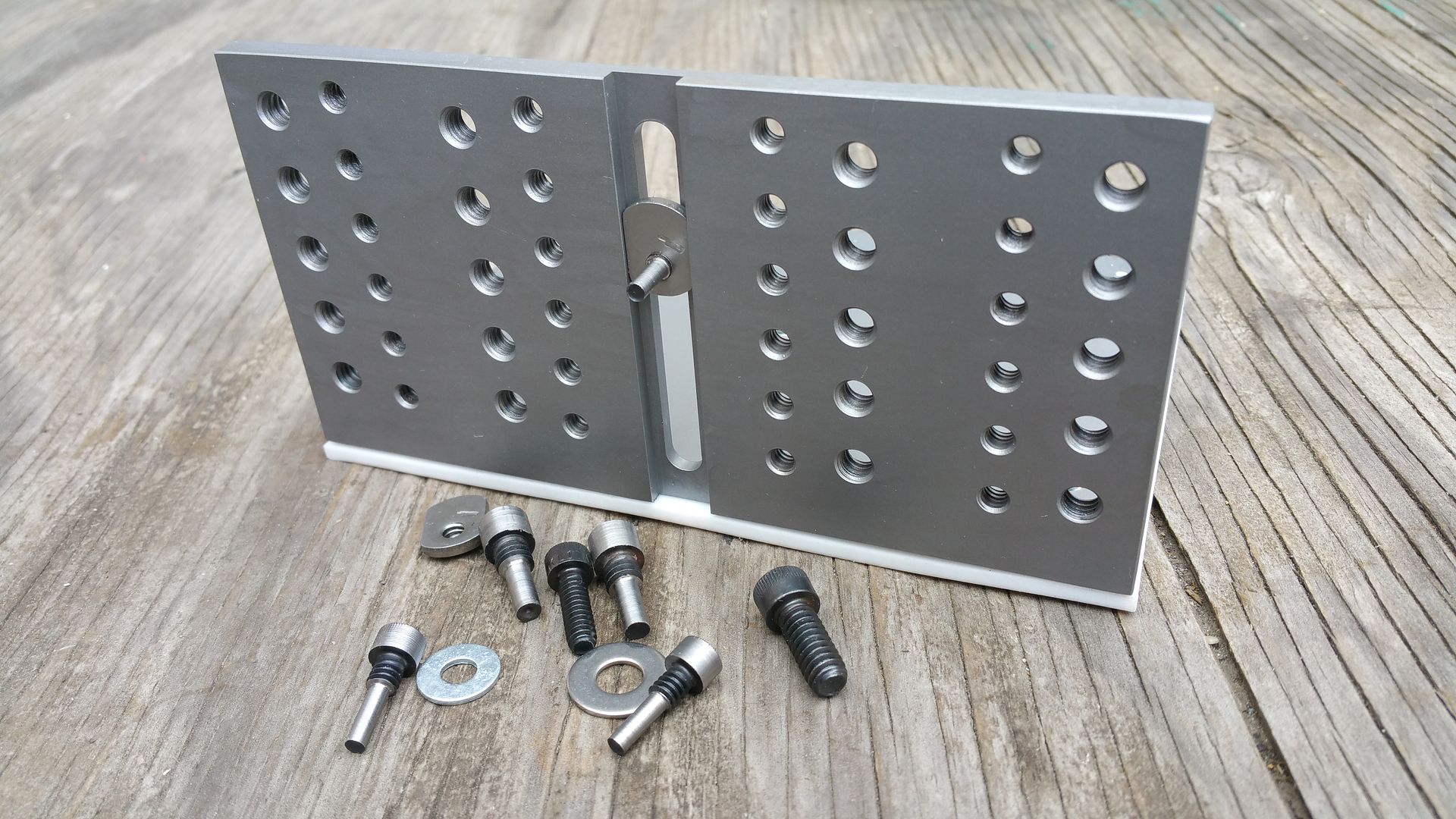

Vise also came in

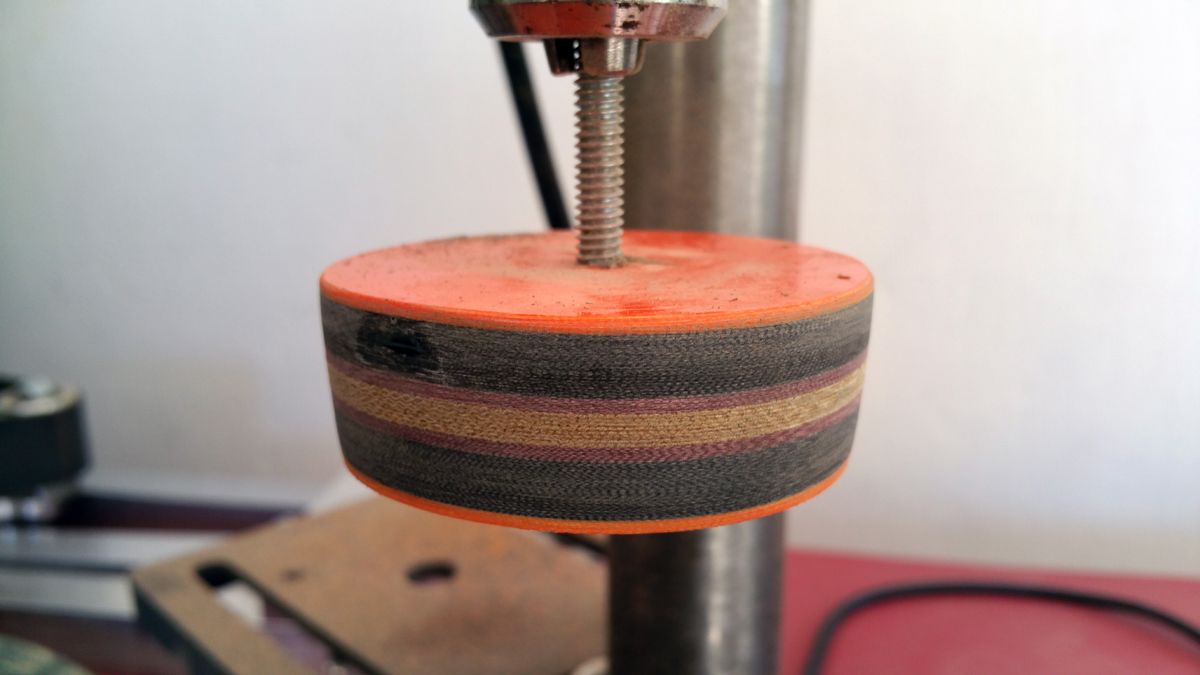

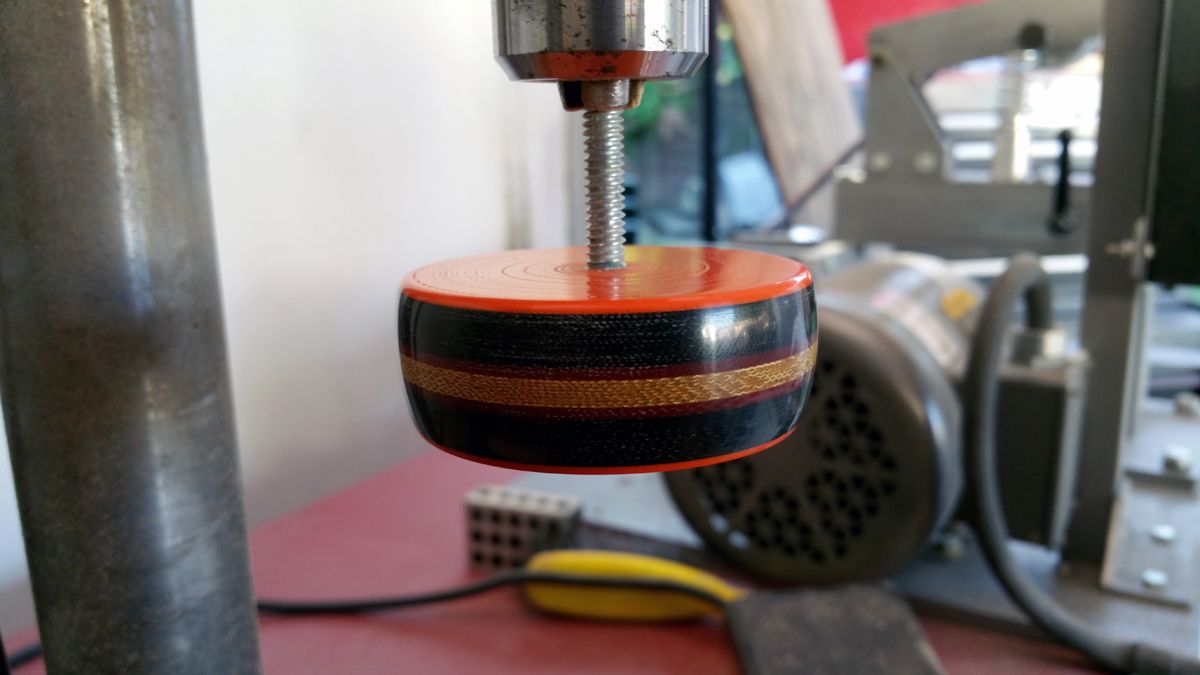

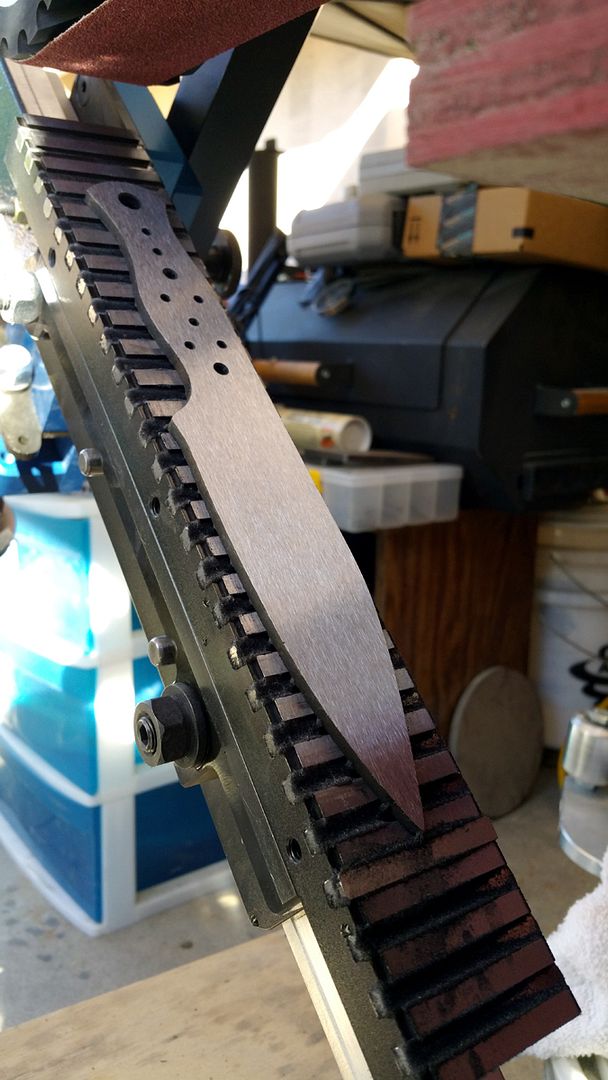

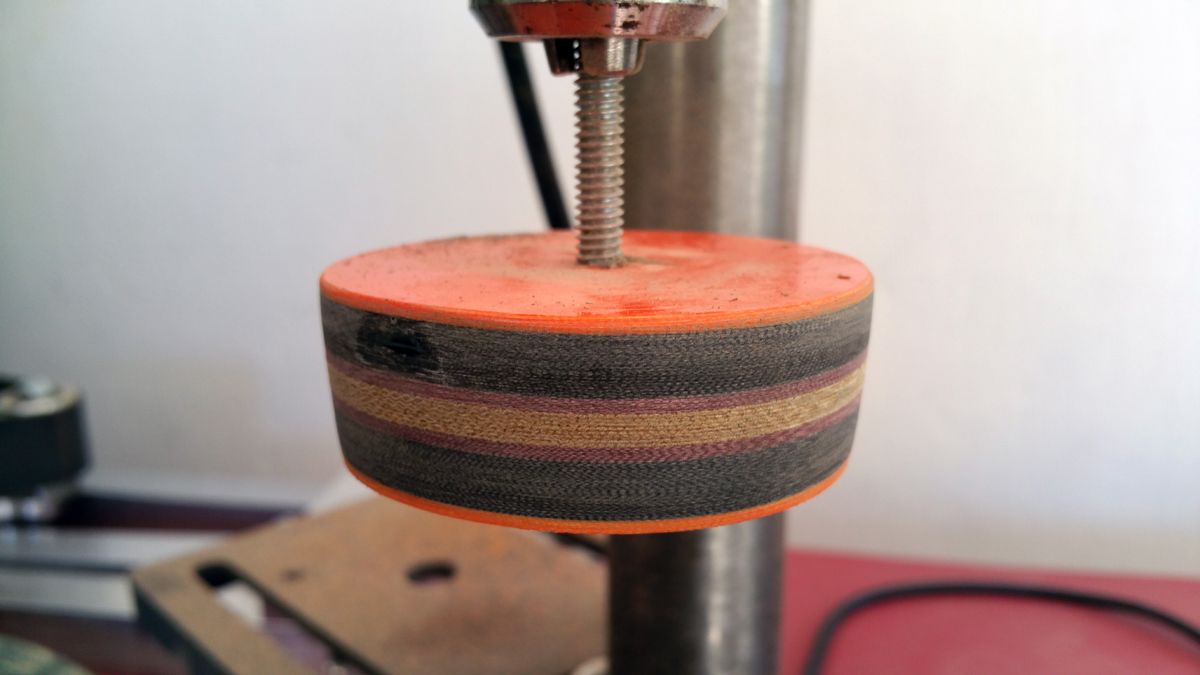

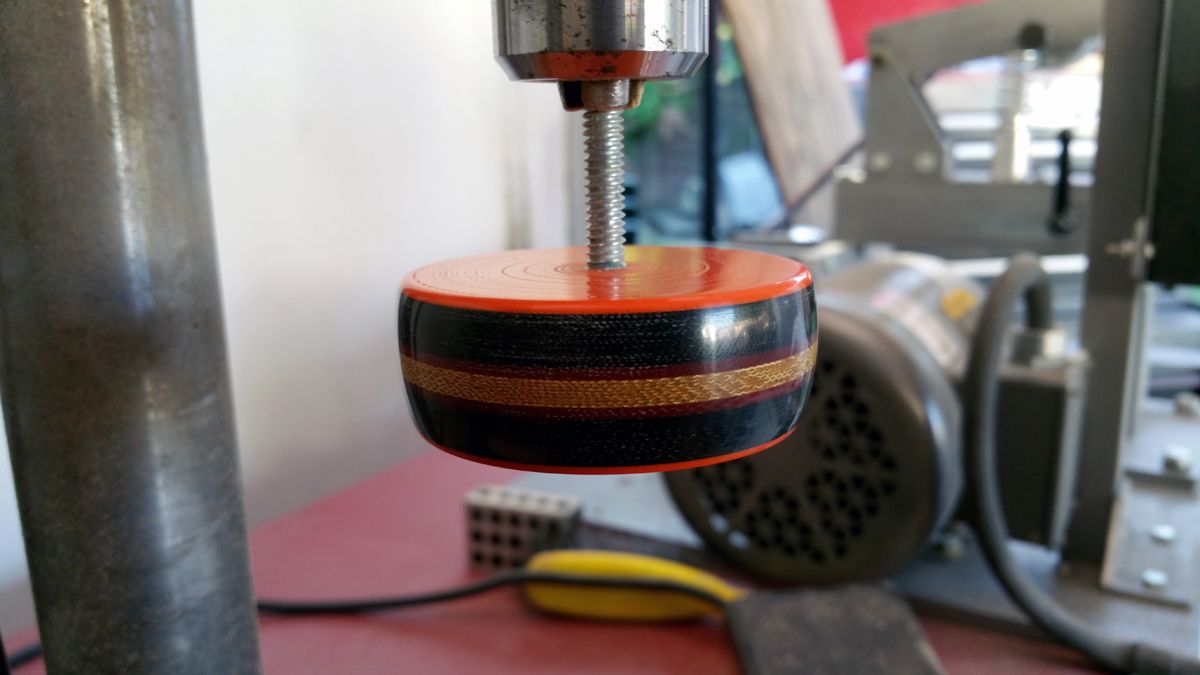

I've been wanting a bigger tracking knob for my KMG a while now, the stock one works great. But too small for constant tracking, as I've been doing on the new surface grinding attachment.

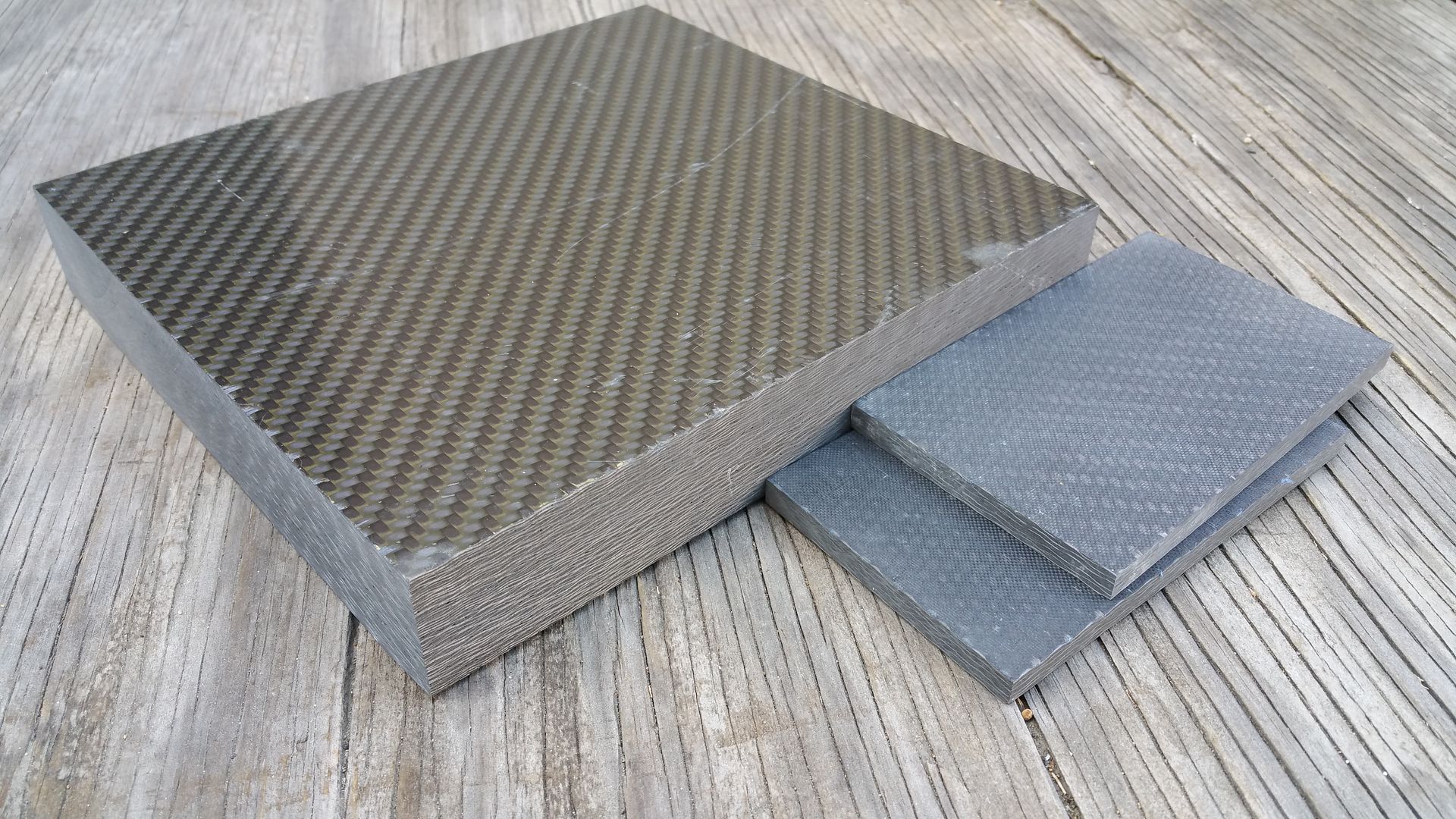

Black G10, Red G10, and Natural Canvas Micarta glued and clamped.

After drying, I drilled a counter-bored hole and passed through a nut and bolt. It was then covered and epoxied with a layer of Orange G10 to hide the bolt. Threw the knob on my drill press and started removing material.

Went through the grits up to 2500

Polished with pink scratchless on the buffer

Setup on the KMG

Old tracking knob next to the new one

Also made an extended tension arm

Put the surface grinder to work today. Got everything rough finished at 60 grit

Before:

After:

Also got a new hammer for bladesmithing and a sweet center punch from Brent Bailey

Got these super sick handle broaches from John Perry. They will be very helpful when I start working on the hidden tang knives.

Roughed out

Smoothed out facets on slack belt to 400 grit

Also made an upgrade to my safety gear after seeing a friend's. Had been wanting a full face, but didn't like the ones I saw prior to this one.

Replaced the old respirator and safety glasses with a full face

Hand sanded another blank for the next knife order.

Did a little warm up blade, before I get started on orders. This is a blade I botched a while back, and decided to keep it as a personal knife.

A2 Steel, Drewcarta handle with black liner. Sanded to 400grit then polished.

Left side of the handle at 400 grit via scalloped slack belt- right straight to the buffer

Finished

Current batch: Did a little more profiling to get it where I want.

Vise also came in

I've been wanting a bigger tracking knob for my KMG a while now, the stock one works great. But too small for constant tracking, as I've been doing on the new surface grinding attachment.

Black G10, Red G10, and Natural Canvas Micarta glued and clamped.

After drying, I drilled a counter-bored hole and passed through a nut and bolt. It was then covered and epoxied with a layer of Orange G10 to hide the bolt. Threw the knob on my drill press and started removing material.

Went through the grits up to 2500

Polished with pink scratchless on the buffer

Setup on the KMG

Old tracking knob next to the new one

Also made an extended tension arm

Put the surface grinder to work today. Got everything rough finished at 60 grit

Before:

After:

Also got a new hammer for bladesmithing and a sweet center punch from Brent Bailey

Got these super sick handle broaches from John Perry. They will be very helpful when I start working on the hidden tang knives.

rhinoknives

Well-Known Member

Gary,

Nice looking work! I'm sure your customer will be happy with that one, I dig the wood scales !

Nice looking work! I'm sure your customer will be happy with that one, I dig the wood scales !

Thanks Laurence.Gary,

Nice looking work! I'm sure your customer will be happy with that one, I dig the wood scales !

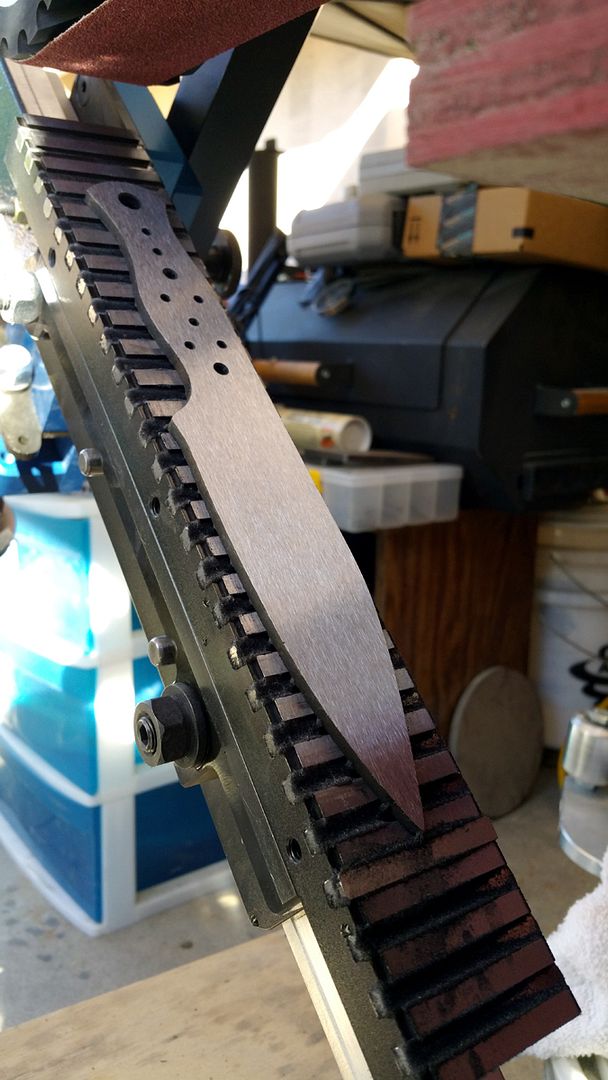

Been needing a new drill press a while now, after my HF benchtop press started really bogging down on steel. And the power switch broke off- which I initially had duct taped back on. Ended up being so weak I could stop the press with my hand. Matt described my press as being so weak, it couldn't even break itself. lol

SO I went big, knowing I planned to make/work on more than just knives.

Nearly broke my back rolling this beast on a dolly to my backyard shop

Here it is waiting for the motor head to be attached.

I couldn't find anyone to help me lift this 150lb+ chunk of metal, then remembered I had an engine hoist.

Thank goodness it was able to reach! Turns out even if I was strong enough, I couldn't lift that high due to my lack of height.

Also quickly learned I need a small stool or stepladder just to change the speeds because my arms can't reach.

SO I went big, knowing I planned to make/work on more than just knives.

Nearly broke my back rolling this beast on a dolly to my backyard shop

Here it is waiting for the motor head to be attached.

I couldn't find anyone to help me lift this 150lb+ chunk of metal, then remembered I had an engine hoist.

Thank goodness it was able to reach! Turns out even if I was strong enough, I couldn't lift that high due to my lack of height.

Also quickly learned I need a small stool or stepladder just to change the speeds because my arms can't reach.