Well, I can honestly say this has been one of the worst years for me, in terms of illness. I've never gotten sick this many times in just one year. Not being able to grind and work on knives is a bit annoying, but I can still draw them.

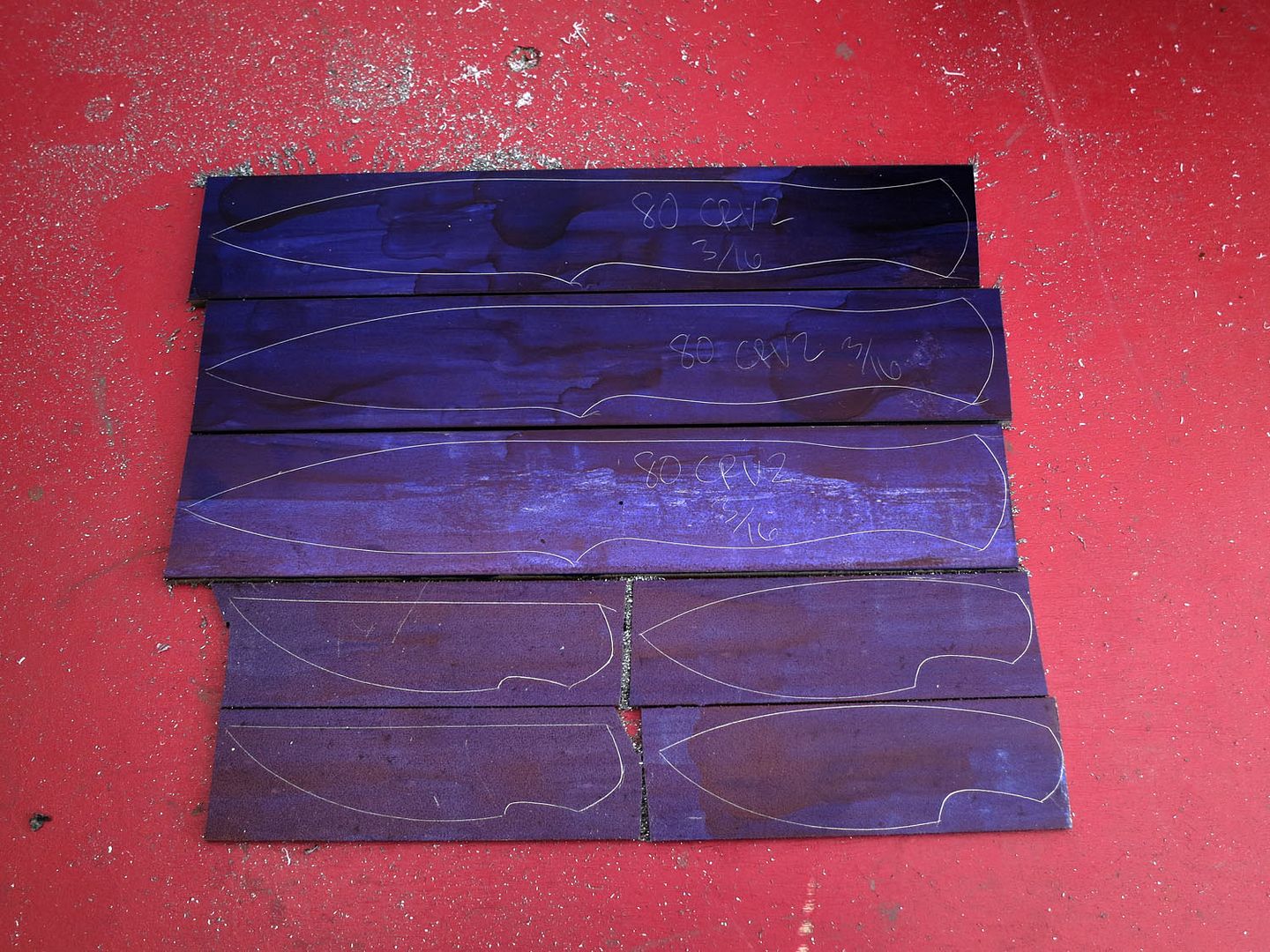

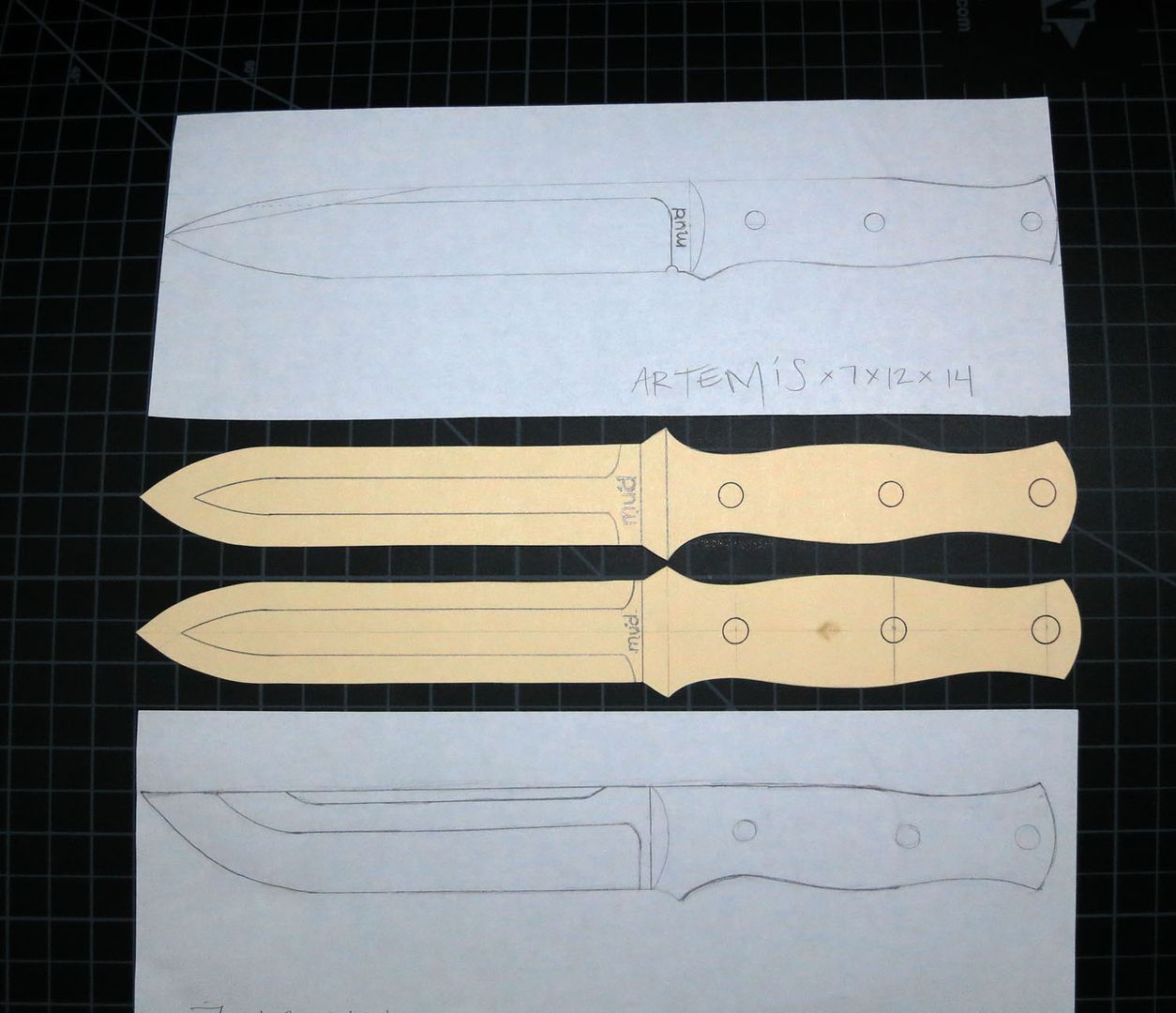

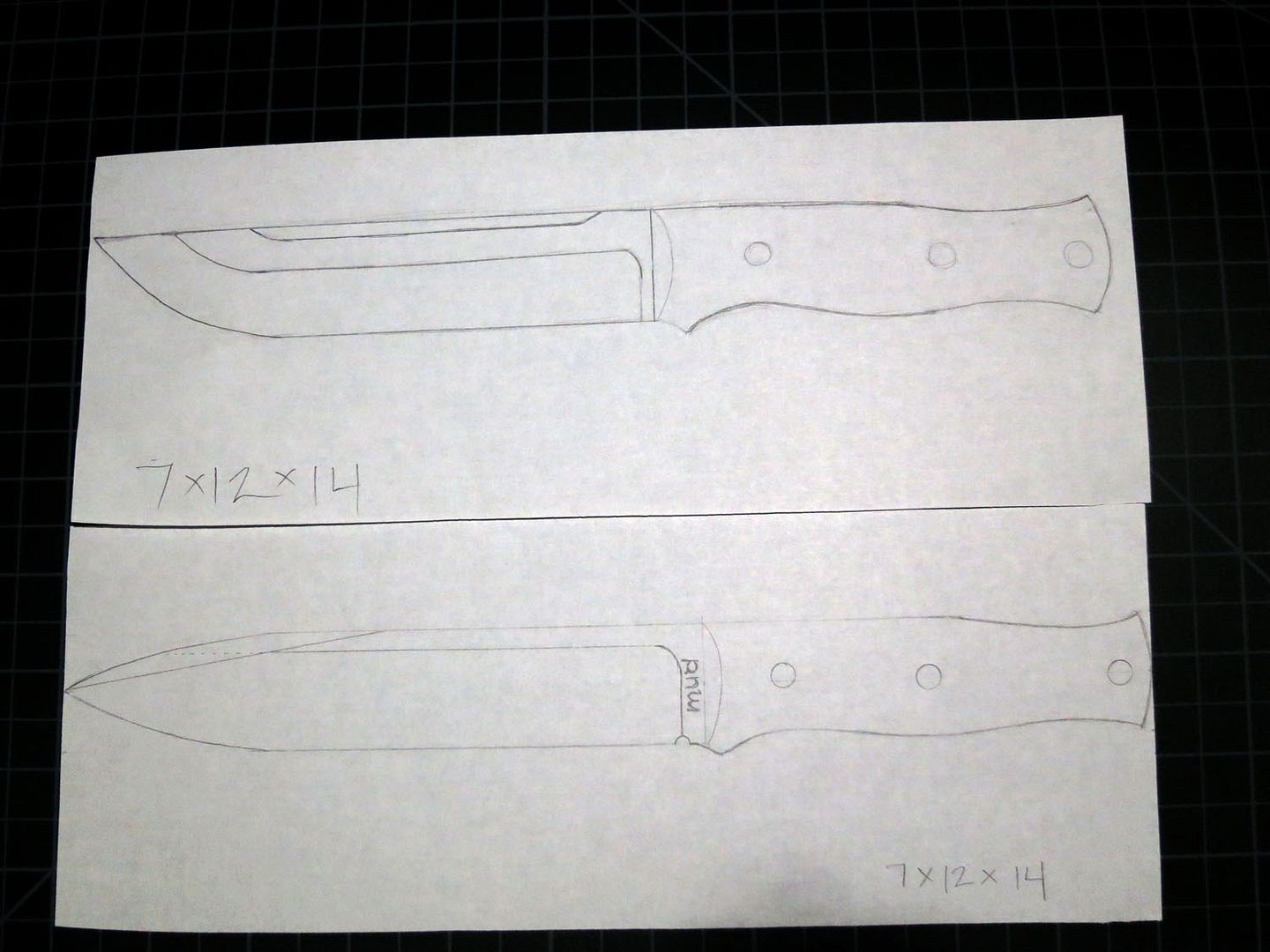

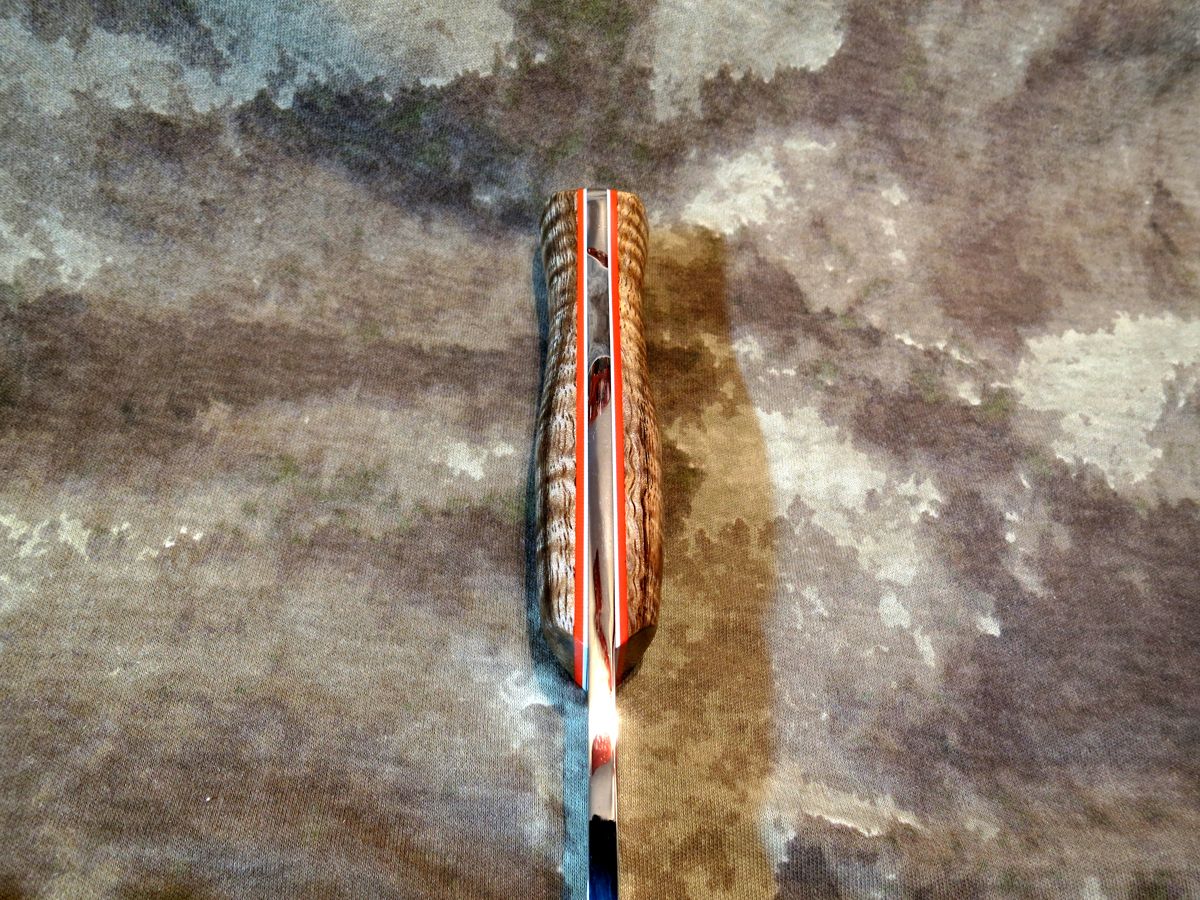

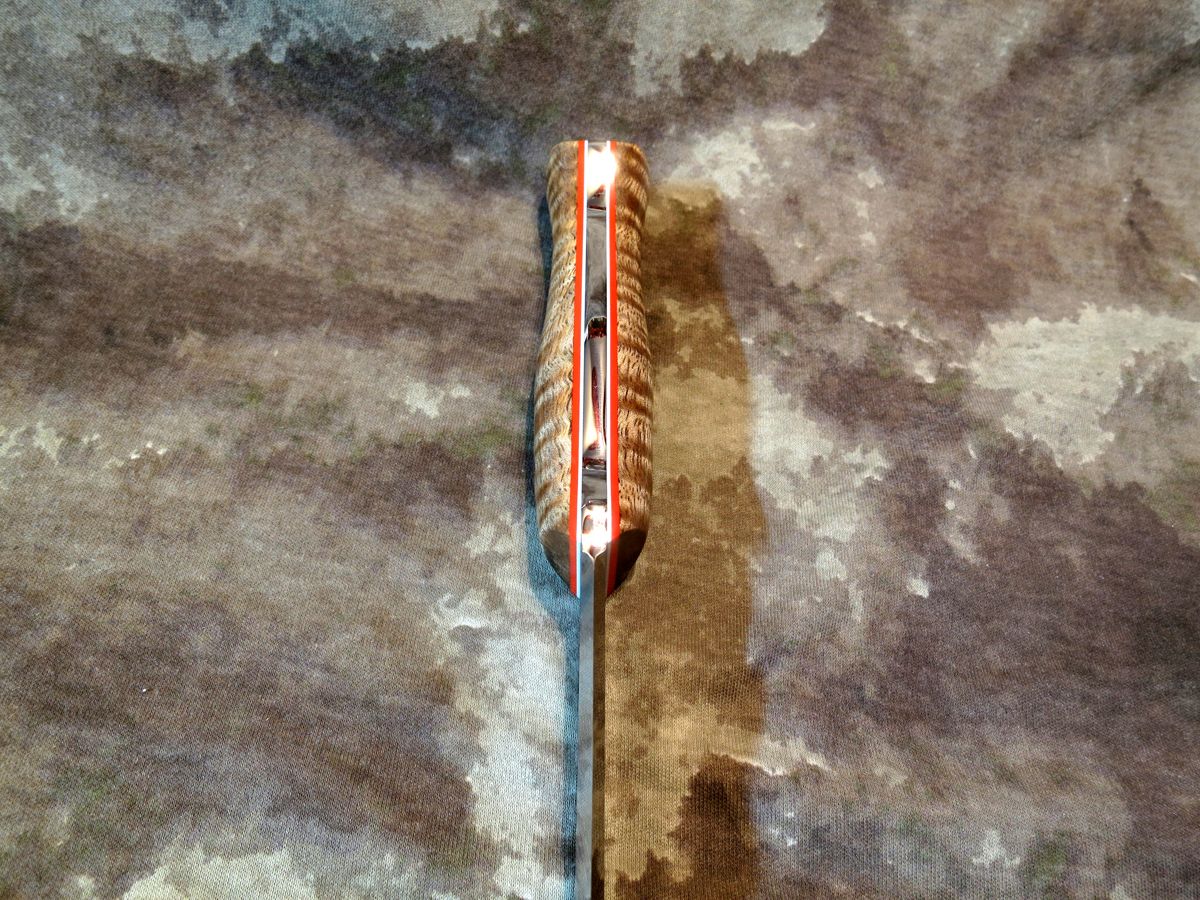

Here are the templates plus a monster one. Think I'll name it the "King"

Here are the templates plus a monster one. Think I'll name it the "King"