Got some more work done today, still down to the wire. I have work in four hours, then hitting the grinder again right when I get home.

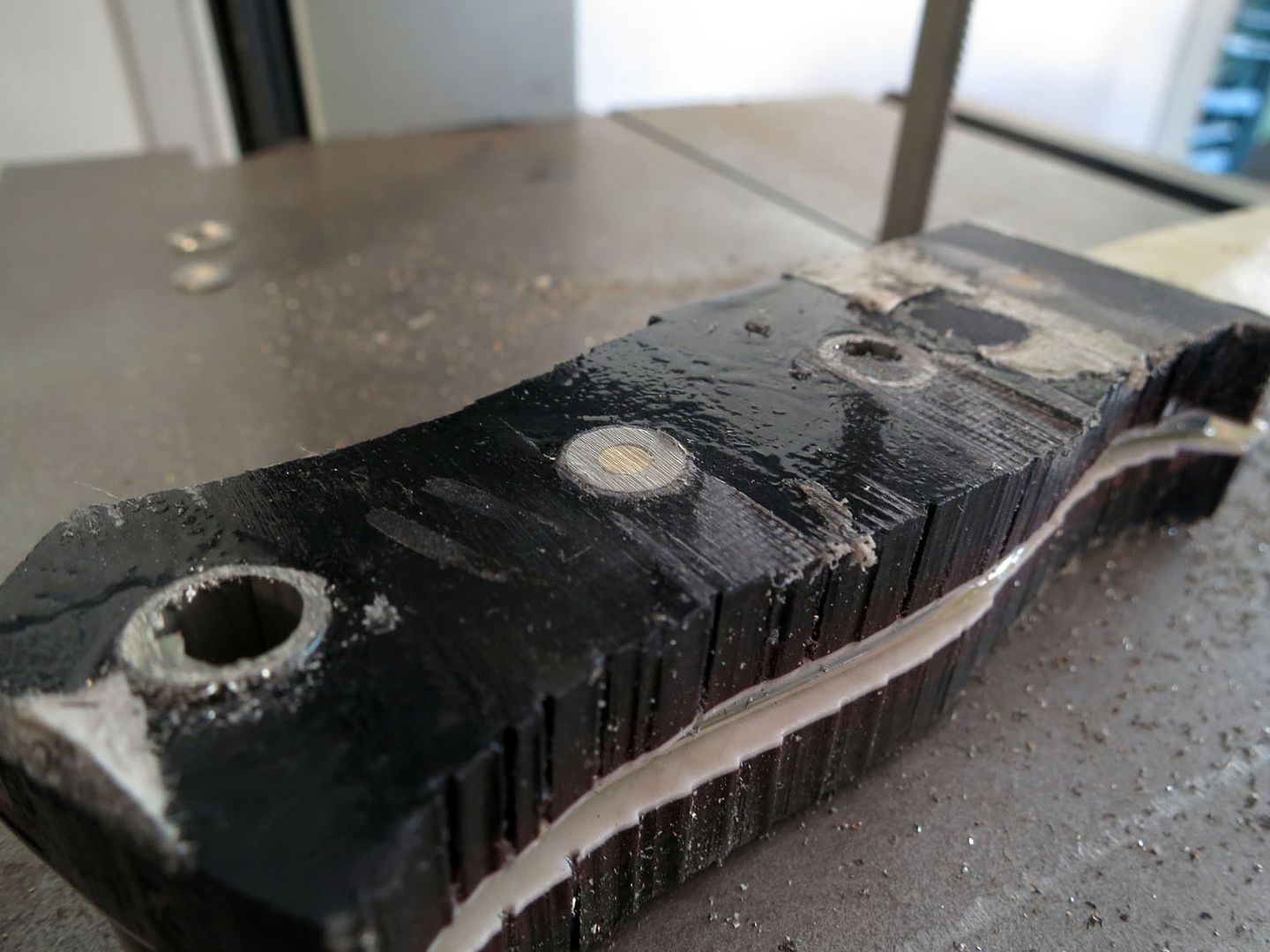

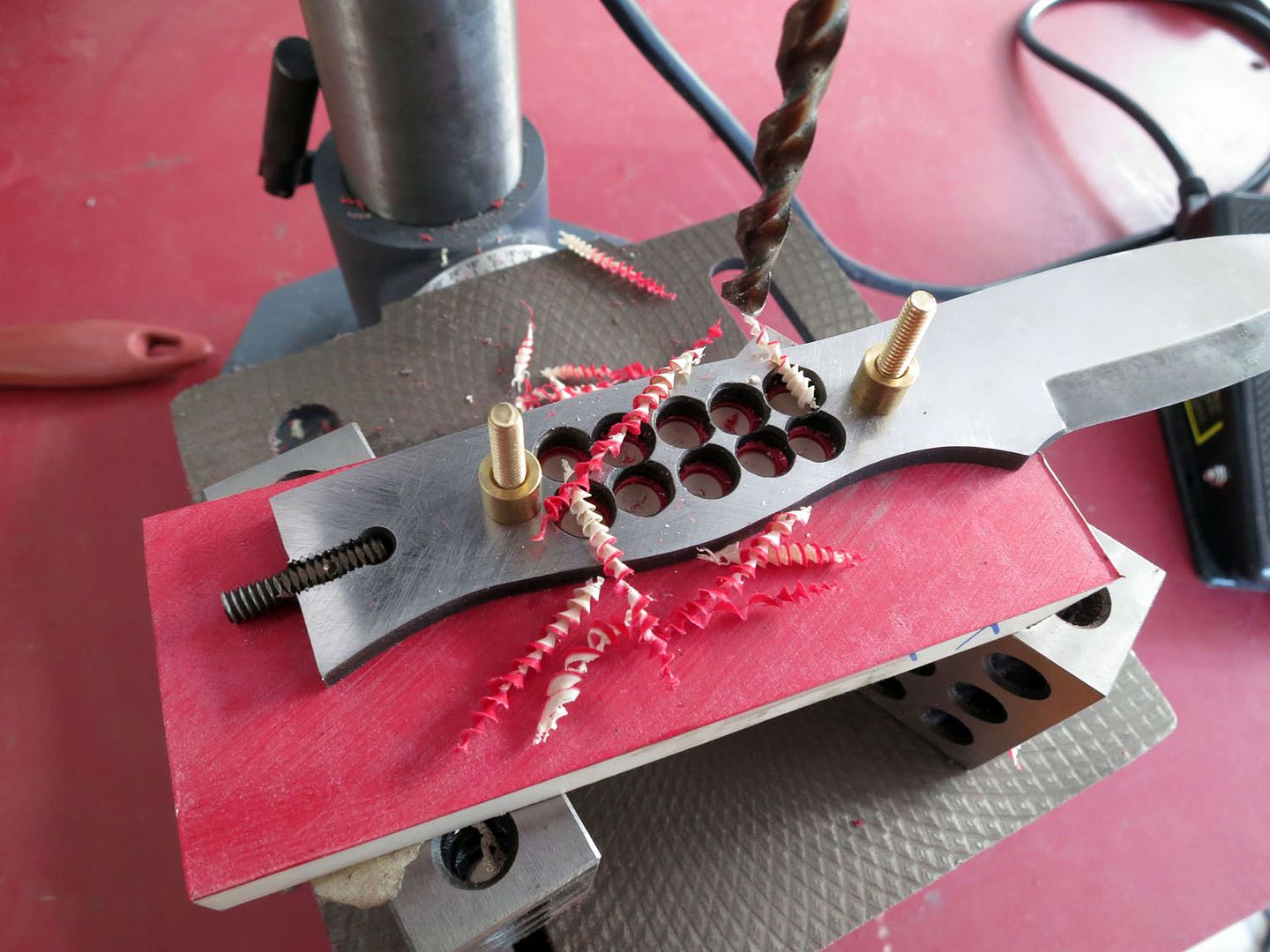

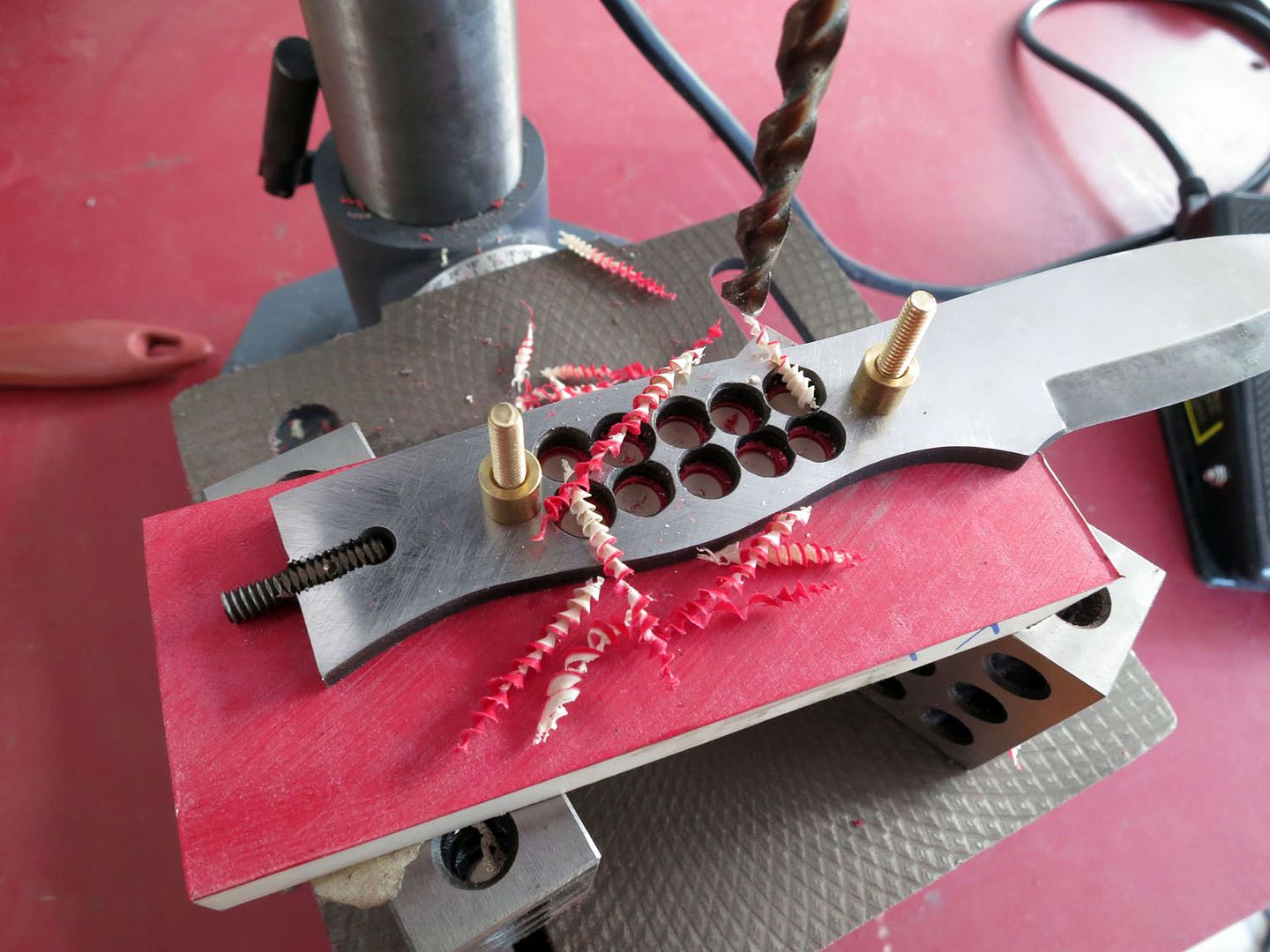

Drilled out holes for Loveless bolts and pins.

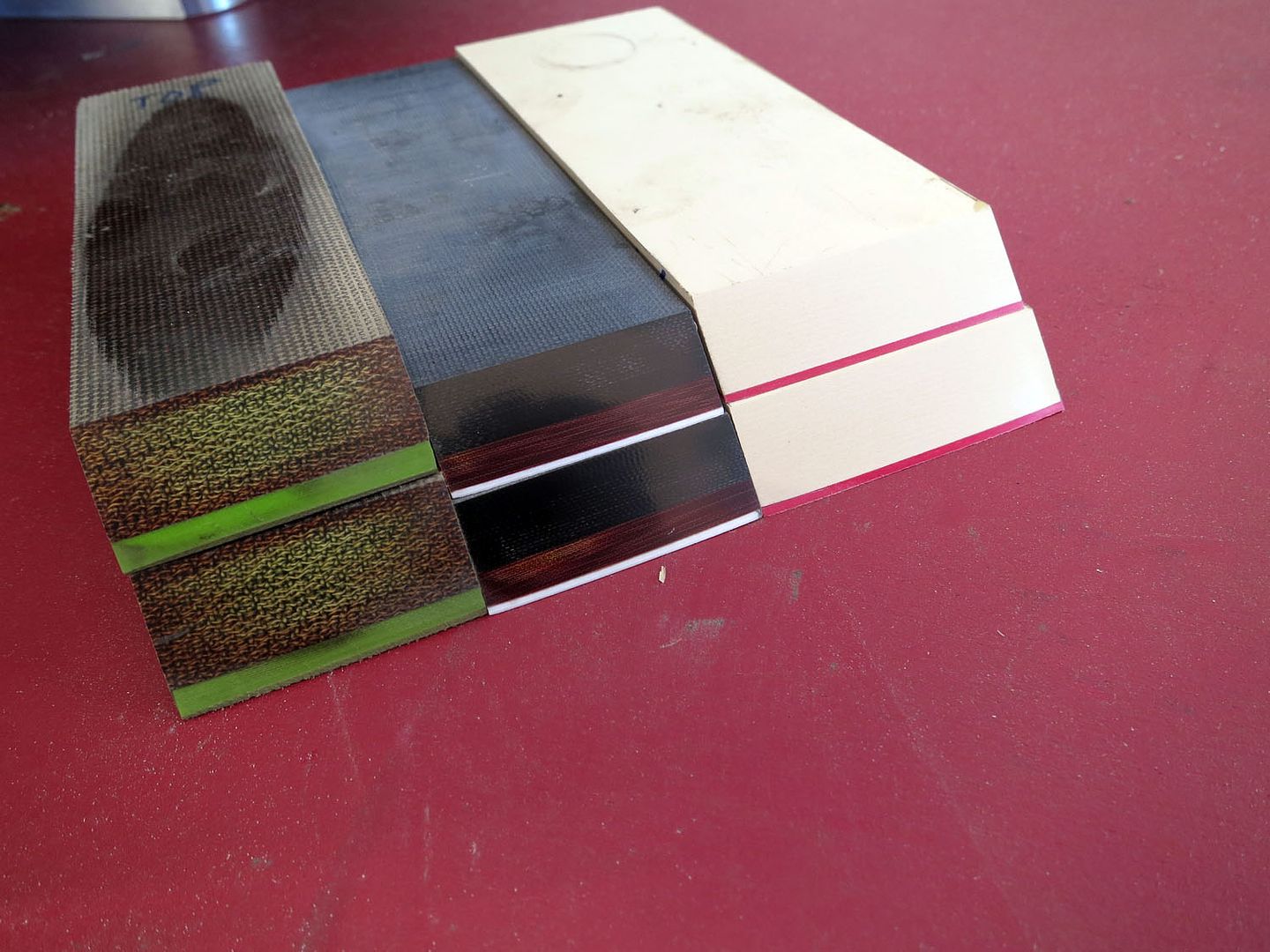

Handle material.

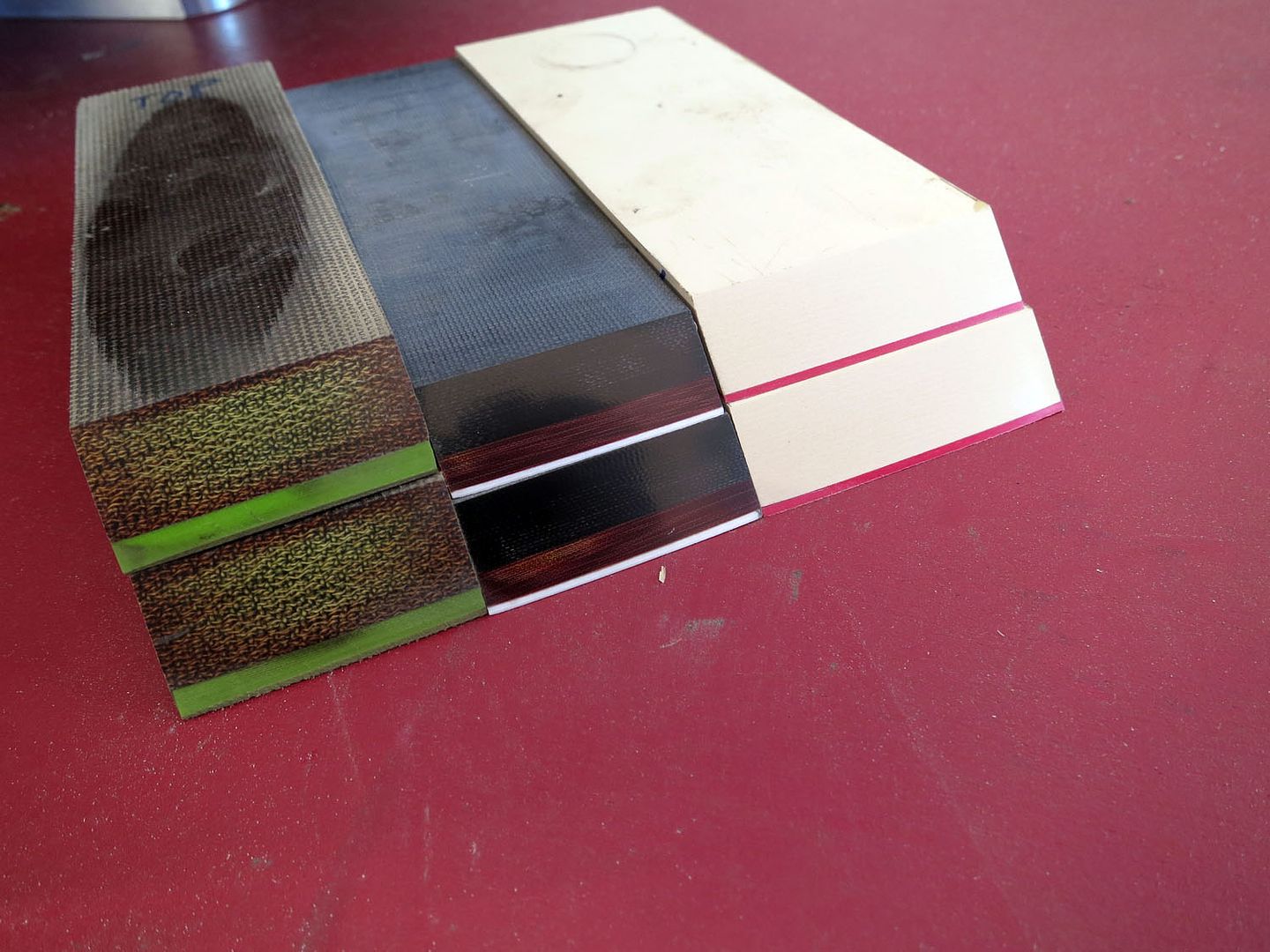

Toxic green liner with green canvas micarta, white and maroon liners with Black linen micarta, red linder with Ivory paper micarta

Drilling out handles a little the give epoxy a bit more of a lock in.

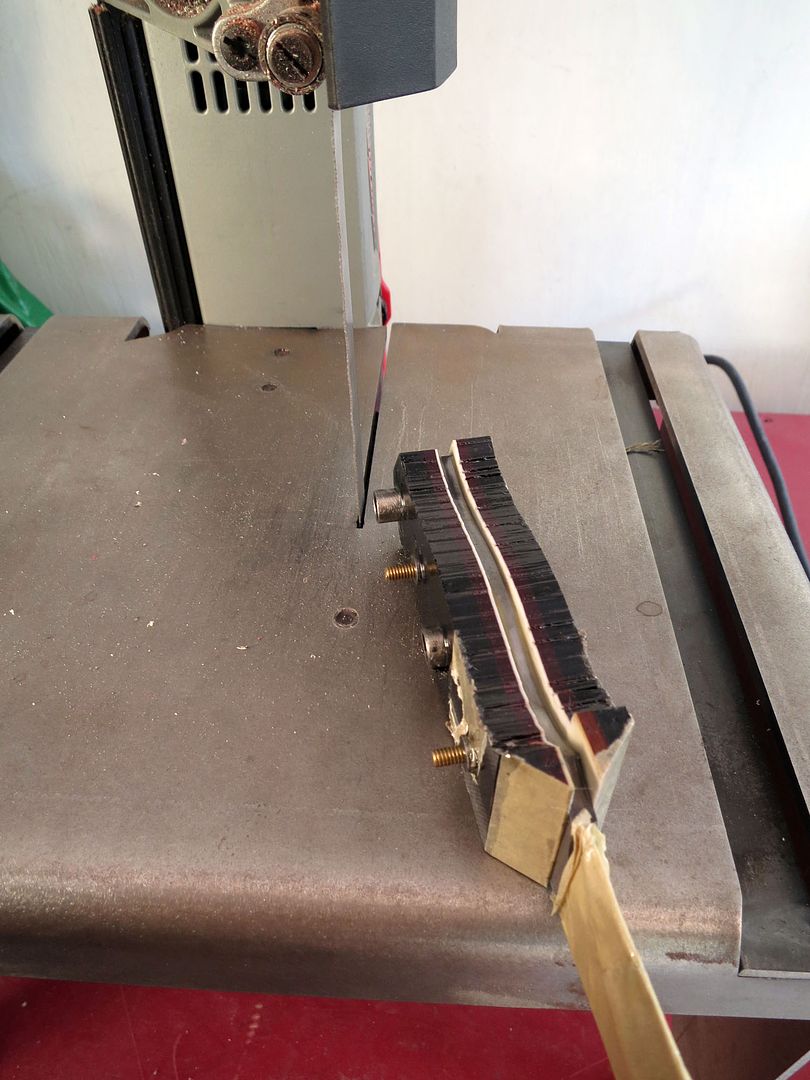

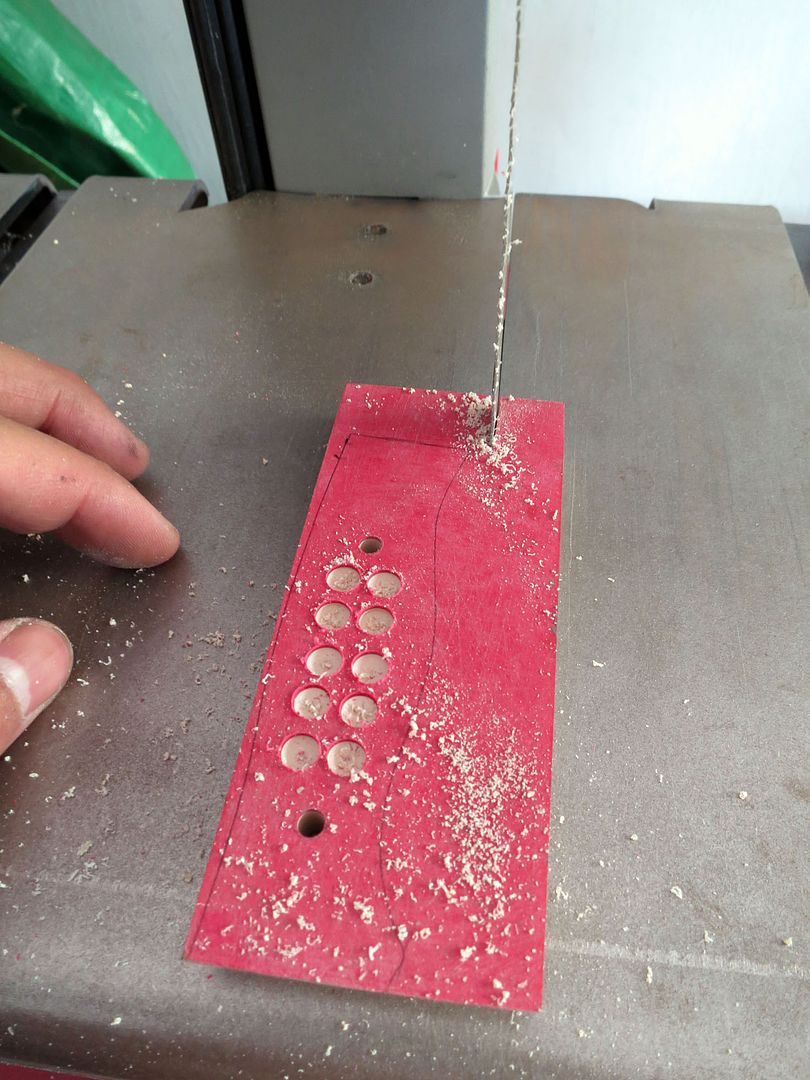

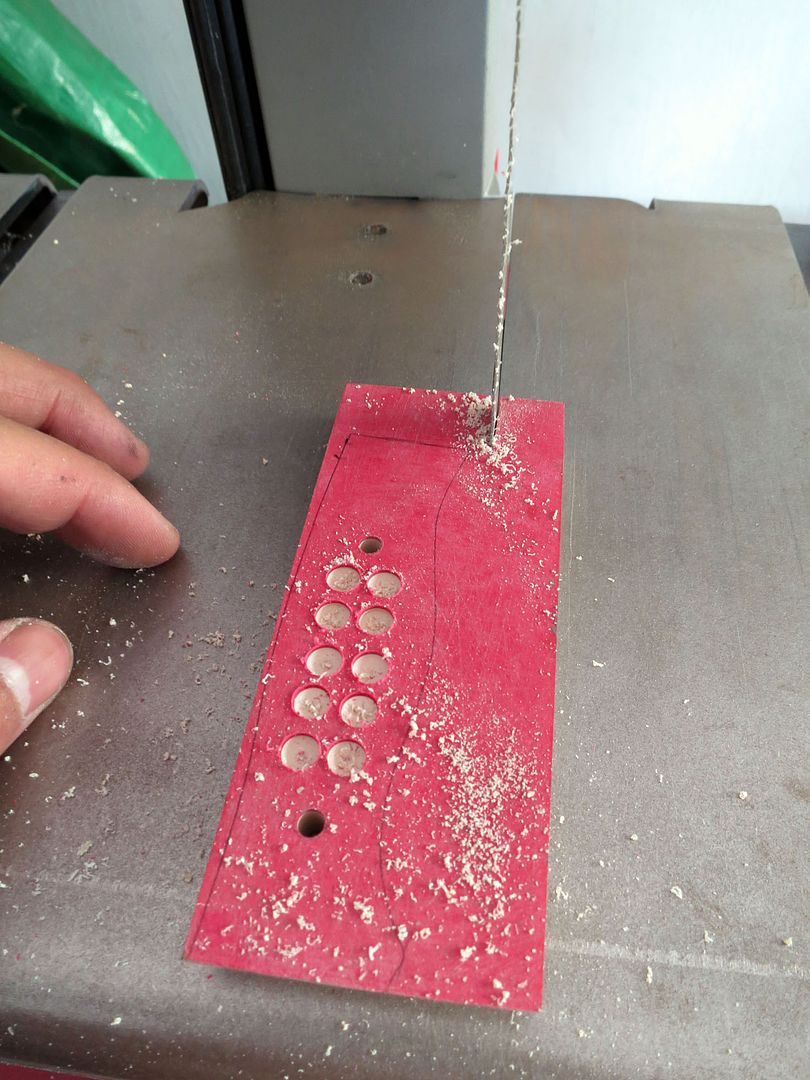

Sawing scale closer to actual size, to save on grinding/sanding time.

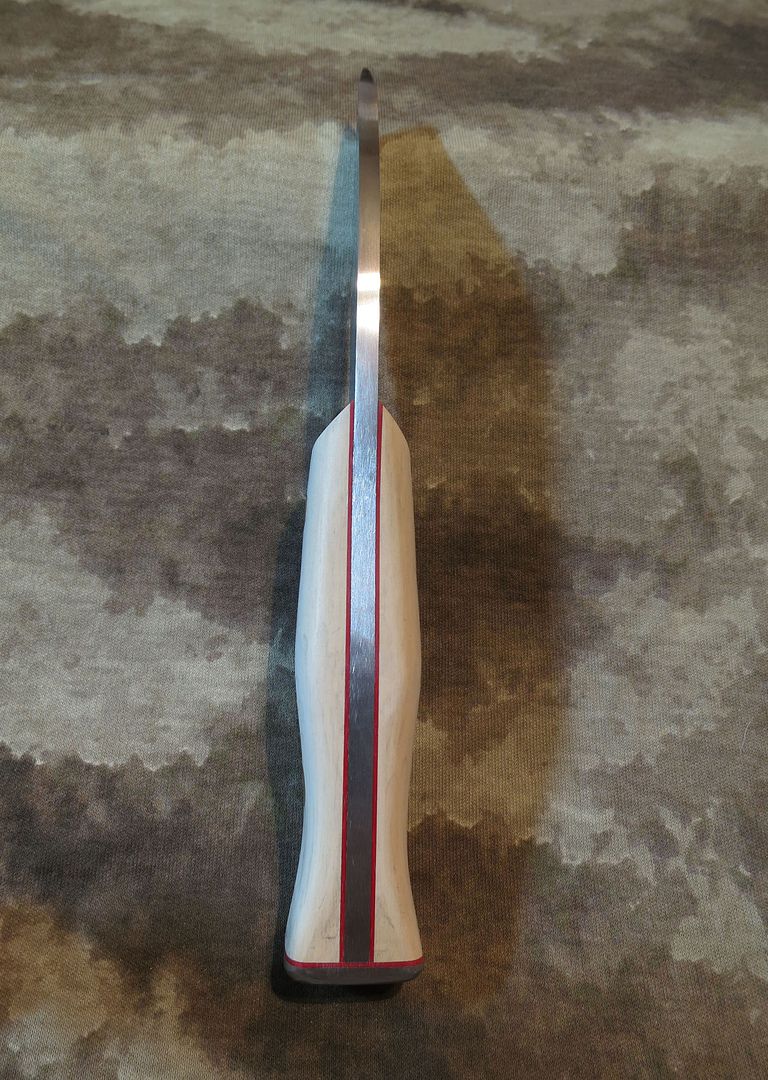

Final edge: I noticed the A2 was much easier to grind, quite noticeable in fact. Although the hardness is the same on both the A2 and O1. I wonder why it's such a noticeable difference.

Roughing up Loveless nuts and 3/8'' tube

Setting up for gluing

Clamped and glued

Hoping to finish these knives on Monday. I have been pleased with everything except the plunge lines. I struggled A LOT with plunges on all 15+ blanks, none of them look half decent. More like a baboon did it while being blind folded and drunk. I know good plunges will come with time- but aside from that, these are looking good so far. Especially for my very first knives.

Another issue is with the steel becoming magnetic, so a demagnetizer is in order when I return from my trip.

Drilled out holes for Loveless bolts and pins.

Handle material.

Toxic green liner with green canvas micarta, white and maroon liners with Black linen micarta, red linder with Ivory paper micarta

Drilling out handles a little the give epoxy a bit more of a lock in.

Sawing scale closer to actual size, to save on grinding/sanding time.

Final edge: I noticed the A2 was much easier to grind, quite noticeable in fact. Although the hardness is the same on both the A2 and O1. I wonder why it's such a noticeable difference.

Roughing up Loveless nuts and 3/8'' tube

Setting up for gluing

Clamped and glued

Hoping to finish these knives on Monday. I have been pleased with everything except the plunge lines. I struggled A LOT with plunges on all 15+ blanks, none of them look half decent. More like a baboon did it while being blind folded and drunk. I know good plunges will come with time- but aside from that, these are looking good so far. Especially for my very first knives.

Another issue is with the steel becoming magnetic, so a demagnetizer is in order when I return from my trip.