Steven Janik

SUPERMOD & AWARDS BOSS

Tracy, with the help of David from Great Lakes Waterjet have come up with the "Bulldog" Framelock kit. The frame and blade are waterjetted and the neccessary harware is included to make a sweet (and large) Titanium framed folder.

Don't think that this is a screw together slammer kit, cuz it's not. But don't think that you can't put this together with some simple power tools. If you have a drill press and a grinder/sander you can come up with a fully functional framelock.

The Boss sold the first six kits at a discount with the stipulation that we get a WIP out of it. So here we go. I made the choice to use the simplest tools I have to show that this doesn't have to be intimidating. I did grind the blade on a 2x72 NWG but did everything else with a small drill press and 4x36 table top sander.

Here's the kit right out of the bag. I sort everything now and put the screws and small parts away.

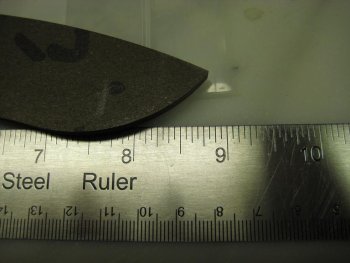

I check the blade thickness, washers and standoff lengths before I start to clean up the blade so I know what I can afford to take off and still be able to use the parts that are included.

Looks like there is plenty of material to get the blade good and clean. I lay it all together and it looks like the overall length will be about 8.875"

With the pieces stacked in the closed position it measures 5".

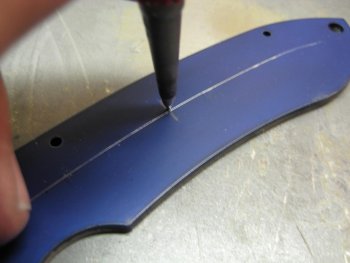

I tape a pc of 180 grit sandpaper on my marble surface plate and clean up the frames while establishing a scratchline. Don't just sand all willy nilly now because you will want a nice even unidirectional scratch on the TI later.

The dark line above the frame turned out to be a dog hair under the paper. I got rid of that and finished the clean up.

more later........

Don't think that this is a screw together slammer kit, cuz it's not. But don't think that you can't put this together with some simple power tools. If you have a drill press and a grinder/sander you can come up with a fully functional framelock.

The Boss sold the first six kits at a discount with the stipulation that we get a WIP out of it. So here we go. I made the choice to use the simplest tools I have to show that this doesn't have to be intimidating. I did grind the blade on a 2x72 NWG but did everything else with a small drill press and 4x36 table top sander.

Here's the kit right out of the bag. I sort everything now and put the screws and small parts away.

I check the blade thickness, washers and standoff lengths before I start to clean up the blade so I know what I can afford to take off and still be able to use the parts that are included.

Looks like there is plenty of material to get the blade good and clean. I lay it all together and it looks like the overall length will be about 8.875"

With the pieces stacked in the closed position it measures 5".

I tape a pc of 180 grit sandpaper on my marble surface plate and clean up the frames while establishing a scratchline. Don't just sand all willy nilly now because you will want a nice even unidirectional scratch on the TI later.

The dark line above the frame turned out to be a dog hair under the paper. I got rid of that and finished the clean up.

more later........

Attachments

-

BULLDOG 001.jpg81.3 KB · Views: 1,898

BULLDOG 001.jpg81.3 KB · Views: 1,898 -

BULLDOG 002.jpg80.3 KB · Views: 1,903

BULLDOG 002.jpg80.3 KB · Views: 1,903 -

BULLDOG 003.jpg94.1 KB · Views: 1,893

BULLDOG 003.jpg94.1 KB · Views: 1,893 -

BULLDOG 004.jpg86 KB · Views: 60

BULLDOG 004.jpg86 KB · Views: 60 -

BULLDOG 005.jpg85 KB · Views: 1,902

BULLDOG 005.jpg85 KB · Views: 1,902 -

BULLDOG 006.jpg87.8 KB · Views: 1,899

BULLDOG 006.jpg87.8 KB · Views: 1,899 -

BULLDOG 007.jpg86.2 KB · Views: 67

BULLDOG 007.jpg86.2 KB · Views: 67 -

BULLDOG 010.jpg86.3 KB · Views: 1,890

BULLDOG 010.jpg86.3 KB · Views: 1,890

Last edited: