Bruce McLeish

Well-Known Member

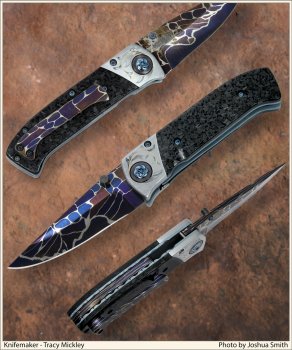

let me know if you have any questions.Probably not. I’m thinking about doing it with the same materials as this knife. Might try to follow Bruce’s tutorial on file work and add some to it. . View attachment 71256

View attachment 71257