It’s been some time since I posted a finished knife. I’ve been mostly out of commission since about Thanksgiving. Feels great to be in the shop again.

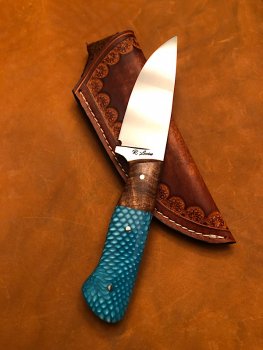

This is one of a 3-knife set. It has been a challenge. The design and some of the elements were a collaborative effort with the customer. The overall design isn’t totally the way I’d have gone with it, but he’s been a good friend for twenty years and I wanted to give him what he wanted.

The hamon / hardening line is very basic. I have a lot to learn in this area, not only with how the clay application will result in the geometry of the line- but how then to develop the activity in that line during etching. It really gives me a deep appreciation for the level of artistry and craftsmanship that guys like John Doyle exhibit.

The handle is Elk antler and olive wood. Of the three knives, this one was the toughest. The customer sent me one large antler and my mission was to get three matching handles out of it. Due to the size and shape of the handle that wasn’t possible, so I went with a 2-piece design to make the most of the antler I had. The liners are G10. Each knife got a specific color liner, chosen by the customer.

The blade is 1075 and the design was a wishlist he gave me. Brut de Forge, visible hammer marks, thumb ramp, harpoon point, hamon.

All in all, I’m happy with how it turned out. The customer is overjoyed, which is what matters to me.