You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's going on in your shop?

- Thread starter Justin Presson

- Start date

Delta Handmade Knives

Well-Known Member

Oops, forgot to post a couple again!

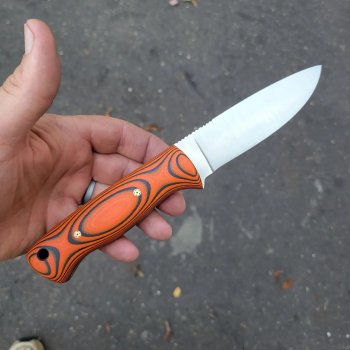

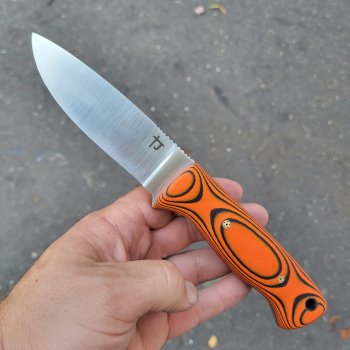

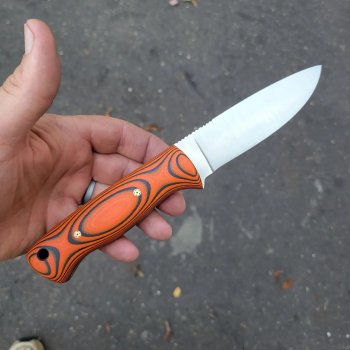

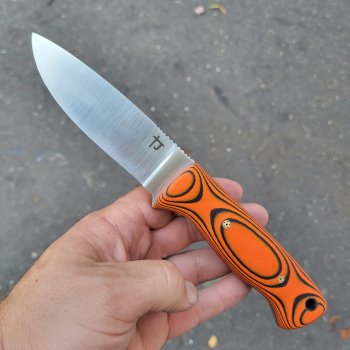

4" Magnacut drop point with orange AmeraGrip handle scales with thick, vintage natural micarta liners. Customer has big hands, so I made the handle a bit chonkier for his hands!

I did a different method for the jimping on this one. I used a side cutting bit in the Dremel to cut them so the bottoms would be rounded. I marked out the spine before cutting into it, but next time, I will use the Cricut and the stencil I used for the electro etching to make it easier to keep the gaps even.

It's just over 3/8" scales and the liners were .070 IIRC? This is before the oil was put on the handle and the orange stays nice and bright!

I've been wanting to do a handrub flat/high polish satin blade bevel for a while, but I struggled getting my grinds dead even to have a flat below the spine to do this with. They usually ended up full flat grinds, so this is my first high flat! Finally got one I was happy with! This is a 3/32" thick magnacut blade, cutting portion of the edge is just over 3", 3.5" tip to handle.

Handle material and guard is a G10 (black, brown, black and tan IIRC)/Copper Laminate from Current Composite. They usually do these laminates where it has a maze pattern on the outer facing side of the block, but this time, they flipped it so the maze patterning is on the side/ends of the scales. One side is awesome, but the other side was more regular just with how the material was folded and pressed.

It is a bit heavier than G10 weight wise, but the copper didn't give any issues heating up or anything, but I worked it slow. It had a black g10 frame.

I grabbed this pic from Currents FB page. You can see a larger chunk of this material at the bottom of the pic and see the folded/ripple pattern on the side of the piece. The blueish piece and red/white/blue pieces standing up is how they normally do it and I really want to get more! They also do it with aluminum as well.

A quick video of it:

I buffed the handle as well and it still has nice grip to it, but youtube downgrades the video quality a bit.

I started this 1/4" thick 80CRV2 blade a while back, so I decided to finish it off! Around 6.75" cutting edge, vintage natural canvas micarta handle, hollow stainless pins and stainless lanyard tube. I did a flat grind and then convexed it, but kept some of the flat below the spine. The convex softened the bevel line, which I was OK with. Still need to sharpen and decide if I am going to straighten the clip out a bit or not and do a sheath for it.

4" Magnacut drop point with orange AmeraGrip handle scales with thick, vintage natural micarta liners. Customer has big hands, so I made the handle a bit chonkier for his hands!

I did a different method for the jimping on this one. I used a side cutting bit in the Dremel to cut them so the bottoms would be rounded. I marked out the spine before cutting into it, but next time, I will use the Cricut and the stencil I used for the electro etching to make it easier to keep the gaps even.

It's just over 3/8" scales and the liners were .070 IIRC? This is before the oil was put on the handle and the orange stays nice and bright!

I've been wanting to do a handrub flat/high polish satin blade bevel for a while, but I struggled getting my grinds dead even to have a flat below the spine to do this with. They usually ended up full flat grinds, so this is my first high flat! Finally got one I was happy with! This is a 3/32" thick magnacut blade, cutting portion of the edge is just over 3", 3.5" tip to handle.

Handle material and guard is a G10 (black, brown, black and tan IIRC)/Copper Laminate from Current Composite. They usually do these laminates where it has a maze pattern on the outer facing side of the block, but this time, they flipped it so the maze patterning is on the side/ends of the scales. One side is awesome, but the other side was more regular just with how the material was folded and pressed.

It is a bit heavier than G10 weight wise, but the copper didn't give any issues heating up or anything, but I worked it slow. It had a black g10 frame.

I grabbed this pic from Currents FB page. You can see a larger chunk of this material at the bottom of the pic and see the folded/ripple pattern on the side of the piece. The blueish piece and red/white/blue pieces standing up is how they normally do it and I really want to get more! They also do it with aluminum as well.

A quick video of it:

I buffed the handle as well and it still has nice grip to it, but youtube downgrades the video quality a bit.

I started this 1/4" thick 80CRV2 blade a while back, so I decided to finish it off! Around 6.75" cutting edge, vintage natural canvas micarta handle, hollow stainless pins and stainless lanyard tube. I did a flat grind and then convexed it, but kept some of the flat below the spine. The convex softened the bevel line, which I was OK with. Still need to sharpen and decide if I am going to straighten the clip out a bit or not and do a sheath for it.

Edwardshandmadeknives

Well-Known Member

Not from the shop today, but I came across this knife today and thought I would share it. This is the earliest knife I have that I made. It got lost and rusty, but still kinda looks like a knife. It’s forged out of an old file, and the handle is ebony, with brass pins. My “forge” at the time was a hole dug in the ground with a hose from a shop vac buried in it to provide air to the bbq charcoal briquettes I used for fuel, and my anvil was a 1/2” plate of steel laying on the ground. I made this one I believe in 1991. I would have been 11 at the time. Kind of neat seeing it 30 some years later.

Edit: the weird choil thing is there because when I hardened it, it cracked, and I ground it out.

That's crazy, 11? Looks good! Your recent work is great too.View attachment 83289

Not from the shop today, but I came across this knife today and thought I would share it. This is the earliest knife I have that I made. It got lost and rusty, but still kinda looks like a knife. It’s forged out of an old file, and the handle is ebony, with brass pins. My “forge” at the time was a hole dug in the ground with a hose from a shop vac buried in it to provide air to the bbq charcoal briquettes I used for fuel, and my anvil was a 1/2” plate of steel laying on the ground. I made this one I believe in 1991. I would have been 11 at the time. Kind of neat seeing it 30 some years later.

Edit: the weird choil thing is there because when I hardened it, it cracked, and I ground it out.

Edwardshandmadeknives

Well-Known Member

Thank you for the kind words. And yeah, I got an early start, lol.That's crazy, 11? Looks good! Your recent work is great too.

I was early at around 17/18 years old when I started in 1998! I think I have that first one at my parents house somewhere. I did a few kits before that, but a machinist friend gave me a piece of O-1, 1/4" thick and around 2" wide. I used a Drill press, hacksaw and files to profile it, and files to file in the bevels. We heat treated it with an oxy acetlyene torch and from what I remember, I put a black linen micarta handle on it. I picked up a Dremel to work on the handles after that and I was hooked! Been doing it off and on since 1998!

Edwardshandmadeknives

Well-Known Member

More addictive than crack, it is. Probably more expensive too, lolI was early at around 17/18 years old when I started in 1998! I think I have that first one at my parents house somewhere. I did a few kits before that, but a machinist friend gave me a piece of O-1, 1/4" thick and around 2" wide. I used a Drill press, hacksaw and files to profile it, and files to file in the bevels. We heat treated it with an oxy acetlyene torch and from what I remember, I put a black linen micarta handle on it. I picked up a Dremel to work on the handles after that and I was hooked! Been doing it off and on since 1998!

I guess my son is only 13 and we're working on his first. That's pretty young in my opinion, but it's surprising what kids are capable of.Thank you for the kind words. And yeah, I got an early start, lol.

I'm letting him do every step. I think it's good even if he never makes knives later. It gets him used to working with his hands.

CDHumiston

Well-Known Member

Love that blade shape and the handle material. I'm a sucker for green!