Chris Railey

Well-Known Member

Awesome Randy, truly.

Second straight day it’s been 115 degrees in the shop so needless to say I haven’t gotten much done.

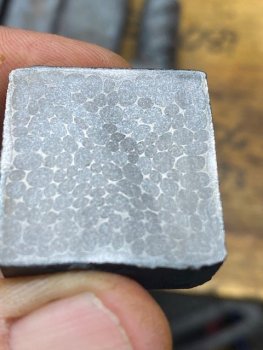

Did you add any powdered steel in the canister or is it all rods and pieces?Quick etch. From a canister I just did. I will cut some off to use as is and then stack and squeeze the rest again for a smaller pattern.

View attachment 73857

That is CRAZY!!Finished this one up today. Working on a “sister” knife to it that has a little more color in the scales. Alabama Damascus and mammoth tooth.

View attachment 73869

View attachment 73870

Ifin ya don't rent pigs , what about goats?

Hey ol friend. It’s a reference to my favorite movie. Lonesome Dove. I usually watch it about twice a year. . I always said if I ever had a sign I was gonna put that on there.Ifin ya don't rent pigs , what about goats?

Got the Two Sisters finished up today except for sharpening. The new owners are happy so that makes me happy.

View attachment 73888

View attachment 73889

It wasn’t bad. Just go slow and use sharp abrasives to keep it from getting too hot. You’re basically working with a rock so it does take some extra time.Beautiful! How difficult is mammoth to work with?

You need to put the "Latin phrase" on the sign too...That way if someone can read it then you can have the "opportunity to shoot at an educated person." Lonesome Dove is at the top of my list too Randy. I knew I liked you.Lonesome Dove

I'll definitely put that on the next sign I make. I was really just playing around trying to learn the machine.You need to put the "Latin phrase" on the sign too...That way if someone can read it then you can have the "opportunity to shoot at an educated person." Lonesome Dove is at the top of my list too Randy. I knew I liked you.

Did you add any powdered steel in the canister or is it all rods and pieces?

from Jeremiah Johnson : "elk don't know how many legs a horse got" (one of my favorite movies)I'll definitely put that on the next sign I make. I was really just playing around trying to learn the machine.

Gus McCrea "A man that won't cheat for a poke don't want one bad enough".

Looking good! A dagger is on my to do list.View attachment 73906

Dagger I'm working on for a customer. Need to do lots of sanding now. Then heat treat. This is gonna get a stone wash in a Citric Acid solution some nice G10 scales, brass pin and Lanyard hole. Pretty happy with grind considering its the first Dagger I've done!