You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's going on in your shop?

- Thread starter Justin Presson

- Start date

Randy Lucius

Well-Known Member

Love the Damascus! Sorry about that thumb, bet that got your attention.Here is a folder sized billet sliced off the bigger billet which turned out not that big but the goal was folder sized.

View attachment 74031View attachment 74032

The patter on the end needs to flip to the side.

View attachment 74038

The billet is cut into even sized chunks.

View attachment 74033View attachment 74034

Stacked and welded. I TIG welded these together so I would have minimal weld metal in the billet.

View attachment 74035View attachment 74036

Here is where I nearly ground my thumb off with a fresh 36 grit belt and all my ample weight applied to it. Sorry I didn't get any bloody pictures.

View attachment 74037

Randy Lucius

Well-Known Member

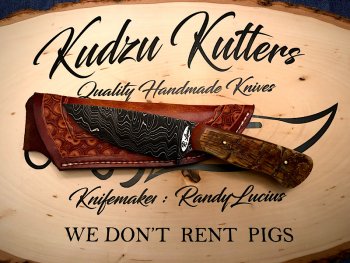

My nephew is a fox hunter and every year they put on a charity hunt for LeBonheur Children’s Hospital in Memphis. Last year they raised over $63,000. I was asked to donate a knife to auction so I’m working on this. Alabama Damascus with Ram’s horn. Got the scales epoxied tonight. I’ll start shaping the handle tomorrow.

Bruce McLeish

Well-Known Member

Ooh la la, mon ami. C'est magnifique!

Daniel Macina

Well-Known Member

Daniel Macina

Well-Known Member

I do believe that is my new favorite you’ve made!My nephew is a fox hunter and every year they put on a charity hunt for LeBonheur Children’s Hospital in Memphis. Last year they raised over $63,000. I was asked to donate a knife to auction so I’m working on this. Alabama Damascus with Ram’s horn. Got the scales epoxied tonight. I’ll start shaping the handle tomorrow.

View attachment 74043

View attachment 74044

Randy Lucius

Well-Known Member

Thanks Daniel! When I shape the handle tomorrow I’m gonna leave as much bark on it as I can.I do believe that is my new favorite you’ve made!

Randy Lucius

Well-Known Member

Ouch Boss Dog! I did that before! Using my Grizzly to hog out blank profiles with a 36 grit Ceramic belt. Tool rest dropped down and my thumb got stuck between the rest and wheel and got ground down until it was thin enough to slip between the wheel and rest. Very painful, but healed up fine!

Randy Lucius

Well-Known Member

Randy Lucius

Well-Known Member

Gliden07

Well-Known Member

Randy im working on a Dion Damascus blade now and want the kind of contrast you have on this blade how do I do it??

Randy Lucius

Well-Known Member

I etch in a 4:1 Ferric chororide solution. 4 parts distilled water to 1 part ferric. Do not use tap water. Add the ferric to the water not the water to the ferric. I usually start with an eight minute etch. Using a soft bristle tooth brush scrub gently under warm running water. Return to ferric and repeat this process as many times as it takes to get some definition between steels. I like to be able to catch my fingernail between them. It really doesn’t take much but you will need some difference between the two. On the last etch do not scrub and rinse. Spray the blade off with windex. Do this away from the ferric. Don’t get the windex in the ferric. I’ve been told that it can kill your solution. After rinsing with windex I use a heat gun to dry the blade and set the last layer of black. After this I do a coffee etch. Using a full jar of instant coffee emptied into a boiler start adding boiling water to the coffee. You want to use as little water as you can. Keep it very concentrated. Once you have your coffee back in a suitable container drop the blade in. Check it after half an hour. If it doesn’t look black enough to you let it sit for another half hour. It’s not going to hurt it. I’ve heard people say they let it sit overnight but I haven’t found that to be necessary. Once you have the color you want rinse the blade off in cool water. Do not scrub. I’ll dry it with the heat gun again and then immediately spray it down with WD40. Before etching I usually finish my blades to 800 grit. The last step is to gently sand with 1000 grit on a hard backer. Start at the ricosso and pull toward the tip. One direction only don’t sand back and forth. Use as little pressure as you can. The idea is just to make the silver pop. Too much pressure and you’ll wipe out some black and get to start this all over again. I’ve done it. That’s pretty much my process. If there’s anything I haven’t been clear on or if you have any questions I’ll be glad to help. Post a pic of that blade when you get it done. I would love to see it.

Last edited:

Randy Lucius

Well-Known Member

Good deal. It may require more than one eight minute dip but you're on the right track.Thank you Sir I'm gonna give it a try on my Caribou handled one Im working on now. I'll just hit it with the 800 again and Ferric dip it again for the 8 minutes then finish like you said.

Gliden07

Well-Known Member

Good deal. It may require more than one eight minute dip but you're on the right track.

Thank you!!

billyO

Well-Known Member

Just to follow up on Randy's etching process. I've read that the coffee will mold or otherwise go bad after a while, but I've been using the same batch for the past 4 years store it in an old milk jug on the bench in the shop and no mold yet, it just seems to be getting darker the more I use it. And I've heard, the cheaper the coffee the better.

Randy Lucius

Well-Known Member

I’m about a year in on this my first batch and so far no problems. Thanks for the comment billy0. Appreciate it!Just to follow up on Randy's etching process. I've read that the coffee will mold or otherwise go bad after a while, but I've been using the same batch for the past 4 years store it in an old milk jug on the bench in the shop and no mold yet, it just seems to be getting darker the more I use it. And I've heard, the cheaper the coffee the better.

Sean Jones

Well-Known Member

Making progress on this Bird and Trout knife. However I've run into a problem with the orange liner on the top side. I have a hole in the liner. I've filled it in several times with matching dust and superglue. I've given it one more try tonight and see if it works. If not...I'll try again

Anyhow here is a couple more photos. I'm almost there.

Anyhow here is a couple more photos. I'm almost there.