Mark Redmon

Well-Known Member

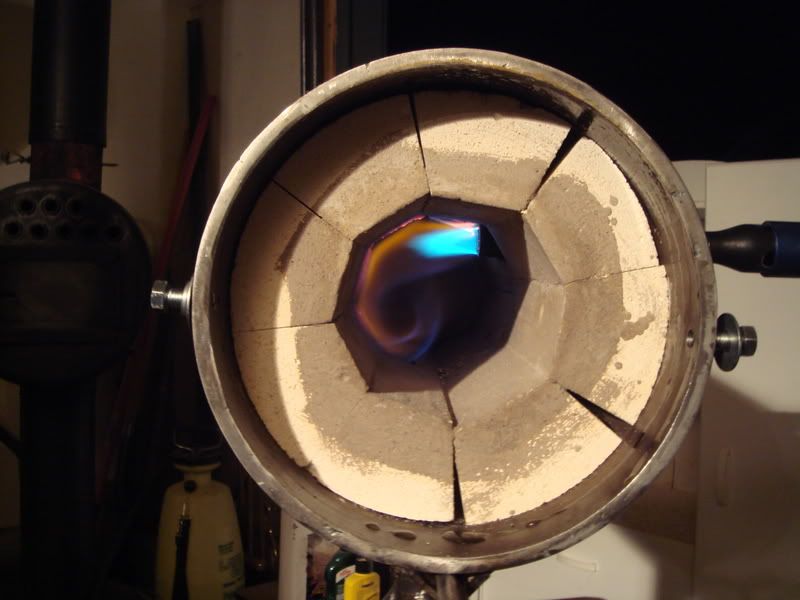

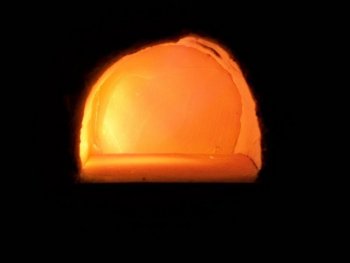

Here's mine. Not the world's best, but it works. It's a Darren Ellis body and burner, btw. I put together the 2 stage burner and control based off of Stacy Apelt's design as well as lined the forge:

Before the lining:

--nathan

Nathan, I don't know if you play any video games, but that looks like something right out of Bioshock! Sweet setup...