You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

World's best thread about forges...

- Thread starter BossDog

- Start date

silver_pilate

Well-Known Member

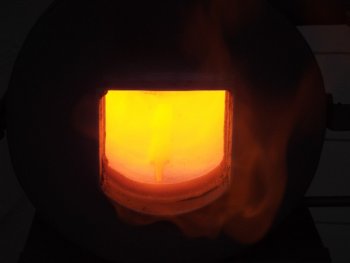

Here's mine. Not the world's best, but it works  . It's a Darren Ellis body and burner, btw. I put together the 2 stage burner and control based off of Stacy Apelt's design as well as lined the forge:

. It's a Darren Ellis body and burner, btw. I put together the 2 stage burner and control based off of Stacy Apelt's design as well as lined the forge:

Before the lining:

--nathan

Before the lining:

--nathan

Last edited:

EdCaffreyMS

"The Montana Bladesmith"

I have all of my forges stacked/crammed onto a table in one corner of the shop.

Welding forge is on the left, and on the right I have a small general purpose forge, and underneath that is a large general purpose forge. The welding forge is a vertical design with a blower, and the general purpose forges are both venturi buners.

Welding forge is on the left, and on the right I have a small general purpose forge, and underneath that is a large general purpose forge. The welding forge is a vertical design with a blower, and the general purpose forges are both venturi buners.

C

CShepherd

Guest

Here's my little forge. It's built out of part of a 120mm Mortar tube. I use a Bernzomatic JTH-7 hooked up to my propane tank from the grill. I bought the lining and satanite from darren Ellis along with a couple of fire bricks.

Works great. I do want to build a larger one sometime in the future. Will probably just save the pennies and buy one pre done from Ellis.

Thanks,

Charlie

Works great. I do want to build a larger one sometime in the future. Will probably just save the pennies and buy one pre done from Ellis.

Thanks,

Charlie

silver_pilate

Well-Known Member

See the difference between a real working forge (Ed's) and a hobbiest forge (mine)

. Ed, I feel like I know your shop from the many times I've seen those forges in watching your videos.

. Ed, I feel like I know your shop from the many times I've seen those forges in watching your videos.

--nathan

--nathan

Raymond Richard

Forum Owner & Moderator

Stacy, Hope you not going for pretty in this thread. Here's my Kashi forge blower made out of a 70 CFM bathroom exhaust fan finished off with a cereal box. The forge was the first propane forge I made probably in 2001 or 02. It was much prettier until it went though the fire in 2005. Its still my all around forge. If its pretty it just won't fit in my shop.

Raymond Richard

Forum Owner & Moderator

Ray, it's good to see someone found a use for something made by Kashi. I hope you didn't eat the contents. I tried once...........once. Never again.

Cereal is cereal. I probably mixed some Coco Puffs into the Kashi. Good stuff!

Here's the oil fired forge I'm currently working on.

That's a 5 gallon bucket next to it for scale The body is 14" diameter 3/8" wall sewer pipe with 5" square tube for the doors.

The body is 14" diameter 3/8" wall sewer pipe with 5" square tube for the doors.

It'll be fired by a Beckett furnace burner running on diesel or #2 heating oil. Also PID controlled with a controller almost identical to the one Nathan is using. I'm actually doing the PID control so it doesn't get too hot. A friend local to me was running one at a hammer-in recently and was hitting what I estimated to be 2700-2800F with it (the pyrometer shot right to 2500F and then we pulled it out so as not to fry it). It will consistently burn a maximum of 1.25 gallons/hr. which will make budgeting for fuel really easy.

I'll post up more pics as I work on it. I've finally got all the parts here, I just have to finish building it.

-d

That's a 5 gallon bucket next to it for scale

It'll be fired by a Beckett furnace burner running on diesel or #2 heating oil. Also PID controlled with a controller almost identical to the one Nathan is using. I'm actually doing the PID control so it doesn't get too hot. A friend local to me was running one at a hammer-in recently and was hitting what I estimated to be 2700-2800F with it (the pyrometer shot right to 2500F and then we pulled it out so as not to fry it). It will consistently burn a maximum of 1.25 gallons/hr. which will make budgeting for fuel really easy.

I'll post up more pics as I work on it. I've finally got all the parts here, I just have to finish building it.

-d

Raymond Richard

Forum Owner & Moderator

Here's the oil fired forge I'm currently working on.

That's a 5 gallon bucket next to it for scaleThe body is 14" diameter 3/8" wall sewer pipe with 5" square tube for the doors.

It'll be fired by a Beckett furnace burner running on diesel or #2 heating oil. Also PID controlled with a controller almost identical to the one Nathan is using. I'm actually doing the PID control so it doesn't get too hot. A friend local to me was running one at a hammer-in recently and was hitting what I estimated to be 2700-2800F with it (the pyrometer shot right to 2500F and then we pulled it out so as not to fry it). It will consistently burn a maximum of 1.25 gallons/hr. which will make budgeting for fuel really easy.

I'll post up more pics as I work on it. I've finally got all the parts here, I just have to finish building it.

-d

Deker, Will this forge of yours run on waste oil? I thought that was the main reason for going with the oil burner.

john smith

Well-Known Member

here is the forge I built last fall. inside is 6" x 14"

line with 2 layers of 1" 8lb cerablanket and coated with plistex 900.

you"ll notice the first couple of photos the nozzle comes in at a higher angle and this gave me a hot spot near the bottom, so I remodeled the inlet and this solved the problem. This is a simple venturi forge with a mig tip in the nozzle from Zoeller Forge.it runs well thru the entire psi range.

line with 2 layers of 1" 8lb cerablanket and coated with plistex 900.

you"ll notice the first couple of photos the nozzle comes in at a higher angle and this gave me a hot spot near the bottom, so I remodeled the inlet and this solved the problem. This is a simple venturi forge with a mig tip in the nozzle from Zoeller Forge.it runs well thru the entire psi range.

Attachments

Deker, Will this forge of yours run on waste oil? I thought that was the main reason for going with the oil burner.

If the waste oil was filtered well and low enough viscosity, I guess it would. I may throw some waste oil into the tank, but I'd never run 100% waste oil. I'd be afraid of gelling in cold weather, nasty gunk from waste motor oil, etc. The reasons I'm going with oil are:

- It's cheaper than propane per gallon.

- It has more BTUs per gallon than propane.

- I can literally flip a switch and the forge is lit. No lighting, no fireballs, no worries.

- It's safer than forced air propane. In the event of a power outage, the forge just stops. No worries about gas buildup in the shop unless I've been eating chili!

- It has a predictable burn rate. I can budget how much shop time will cost more effectively.

- It can run H-O-T. Stainless damascus will be on the menu!

- It can run H-O-T. Small wootz melts can be run in the forge.

- It's different, and just freakin' cool!

-d

Raymond Richard

Forum Owner & Moderator

If the waste oil was filtered well and low enough viscosity, I guess it would. I may throw some waste oil into the tank, but I'd never run 100% waste oil. I'd be afraid of gelling in cold weather, nasty gunk from waste motor oil, etc. The reasons I'm going with oil are:

- It's cheaper than propane per gallon.

- It has more BTUs per gallon than propane.

- I can literally flip a switch and the forge is lit. No lighting, no fireballs, no worries.

- It's safer than forced air propane. In the event of a power outage, the forge just stops. No worries about gas buildup in the shop unless I've been eating chili!

- It has a predictable burn rate. I can budget how much shop time will cost more effectively.

- It can run H-O-T. Stainless damascus will be on the menu!

- It can run H-O-T. Small wootz melts can be run in the forge.

- It's different, and just freakin' cool!

-d

Make sure you post somemore pictures when you get it fired up.

Jeff Pearce

KNIFE MAKER

Don't laugh at mine. i need to build a new one.

If the waste oil was filtered well and low enough viscosity, I guess it would. I may throw some waste oil into the tank, but I'd never run 100% waste oil. I'd be afraid of gelling in cold weather, nasty gunk from waste motor oil, etc. The reasons I'm going with oil are:

- It's cheaper than propane per gallon.

- It has more BTUs per gallon than propane.

- I can literally flip a switch and the forge is lit. No lighting, no fireballs, no worries.

- It's safer than forced air propane. In the event of a power outage, the forge just stops. No worries about gas buildup in the shop unless I've been eating chili!

- It has a predictable burn rate. I can budget how much shop time will cost more effectively.

- It can run H-O-T. Stainless damascus will be on the menu!

- It can run H-O-T. Small wootz melts can be run in the forge.

- It's different, and just freakin' cool!

-d

where are design details on this? I'm interested.

I really would like a PID on mine.

Make sure you post somemore pictures when you get it fired up.

Oh you bet I will!

I hope to be working on finishing it up over the weekend while I'm working on an order or two. Basically I have to weld up a stand for it, finish welding on a few brackets, etc to hold things together, and then get it lined and fired up. It's going to be a bit crazy.

Honestly this will just be the pattern welding forge and I want to be able to work 4"x4" billets, so it had to be a monster. I've got to make some new press dies before I can handle the big billets though.

-d

where are design details on this? I'm interested.

I really would like a PID on mine.

I'll try to get some pics and document it as I go along. The big cutting and welding I farmed out to my local fab shop since I just don't have the tools for stuff like cutting 3/8" wall pipe...They just threw it on the bandsaw!

It's pretty simple in operation though. The controller I got is very simple and will basically just hold a set point. It has an internal 10A relay that will be driving the burner since it will pull a max of 5.6A. I'll show the wiring in a picture or two. I even went all out and got the fancy industrial head pyrometer so that I could permanently mount it on the forge via a 1/2" NPT threaded fitting.

-d