Chef Niloc

Well-Known Member

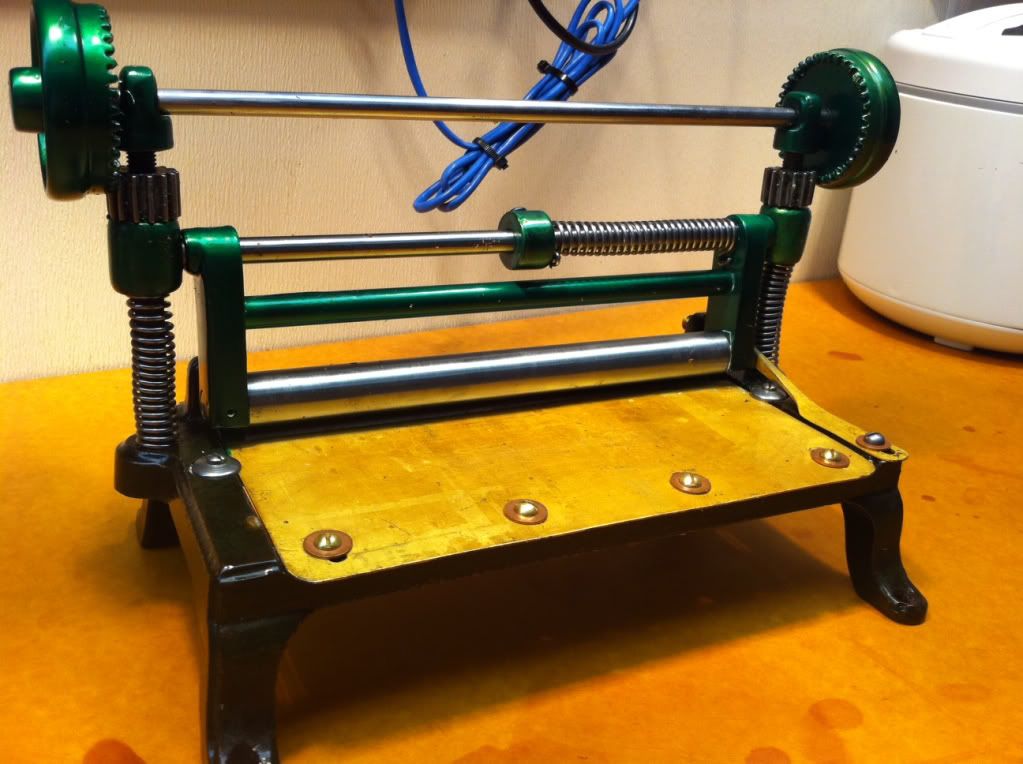

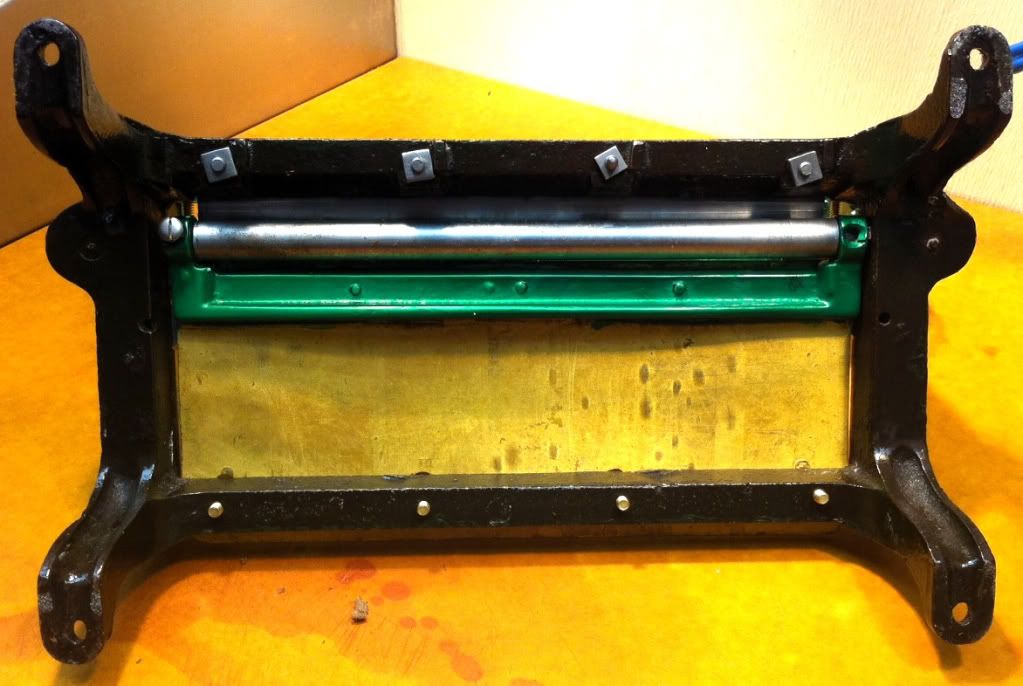

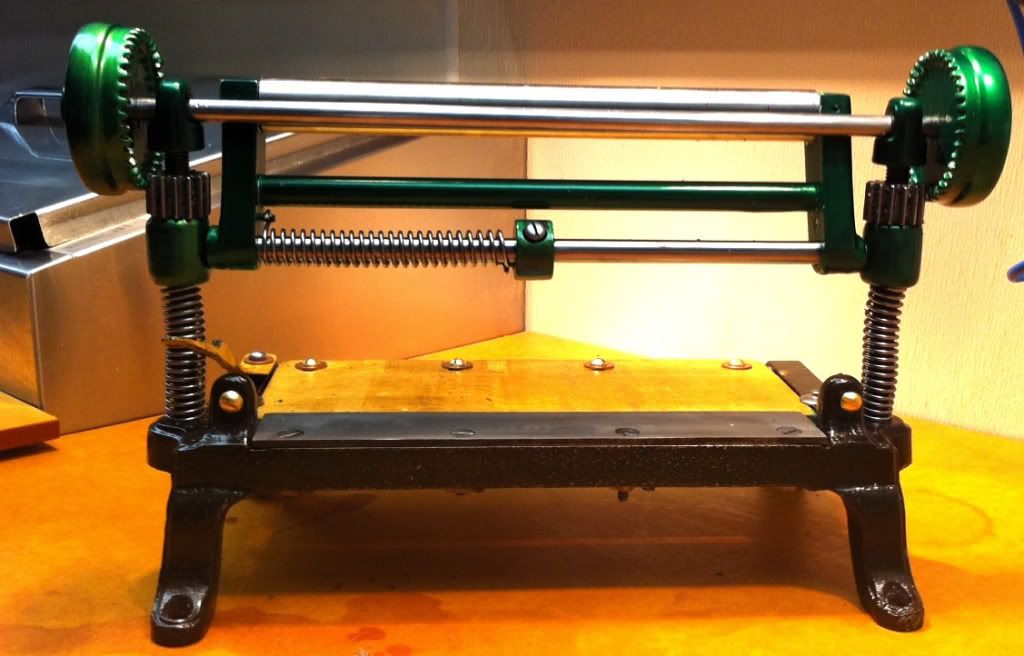

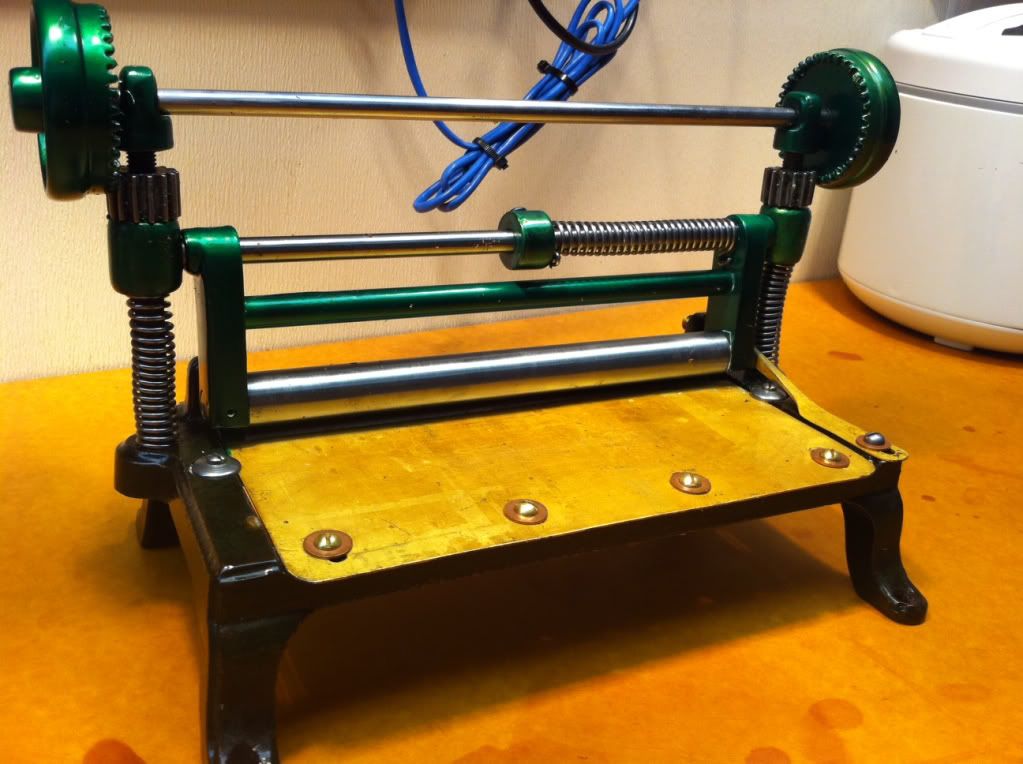

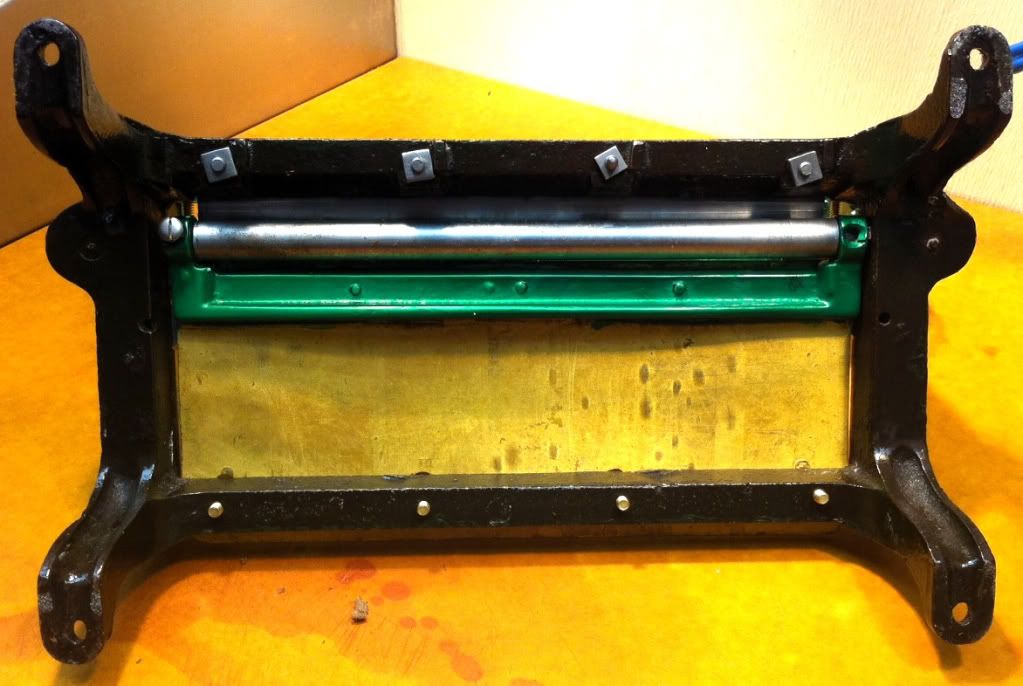

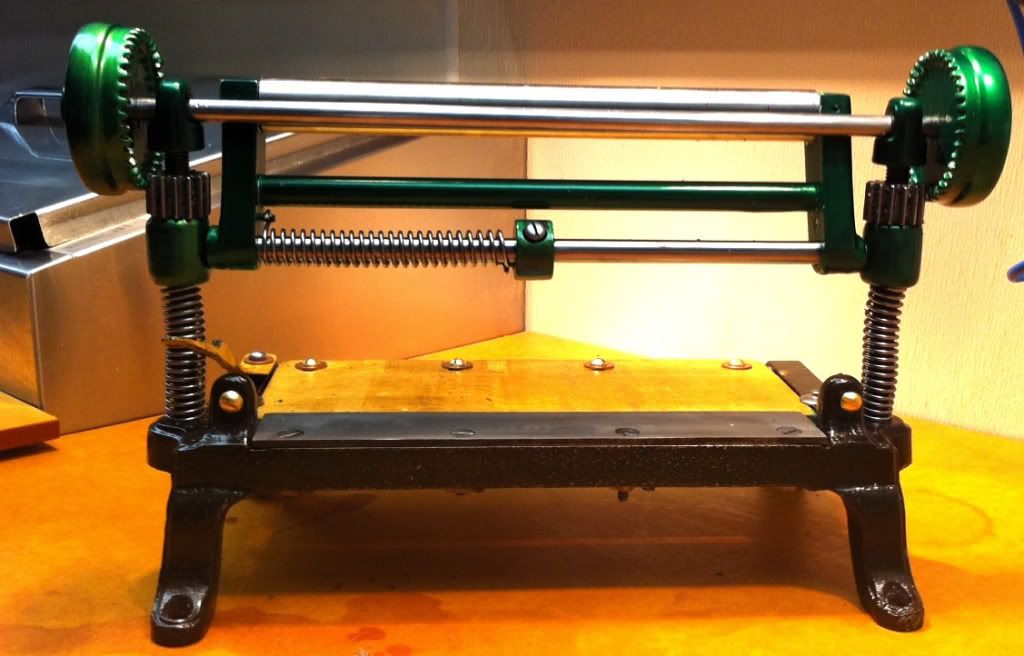

After keeping my eye on eBay for a year or so and lousing a few bids along the way I finally scored me a splitter. It was in kind of bad shape and pretty rusty so I decided to restore it. I took it apart and cleaned the rust and old paint off using a steel brush and sand paper for the big parts and a vibration media tumbler for the smaller parts. Some of the screws I switch out for brass just because I thought it looked better ( I kept the original hardware, in a safe spot just incase). From what I could find the organelle one was panted green, kind of like a landis. I went with a more modern automotive pearl base coat and candy apple green top coat, body shop close by let me use his stuff. There was some gold residue on the base plate I did not know it it was paint or not? I decided to go all out bling bling and gold leaf it, had some old leaf sitting around from my collage art class days. The body it's self was also painted green in a old photo that I found but when I cleaned the rust off what was left was a nice black oxside patina, so I just clear coated it and left it black.

here are some before and after picks.

Before:

After

AND After Master Smith (MS) Michael Rader new blade made from 52100 steel RC 62

here are some before and after picks.

Before:

After

AND After Master Smith (MS) Michael Rader new blade made from 52100 steel RC 62

Last edited: