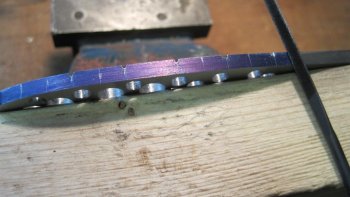

heat treating

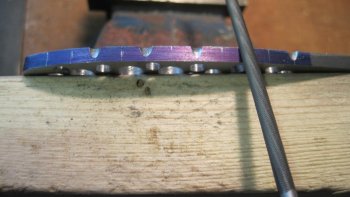

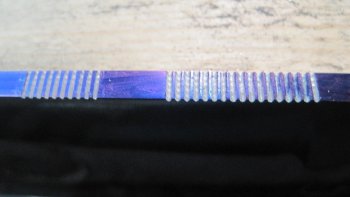

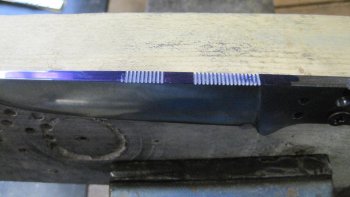

I'm thinking about heat treating this O1 knife. I had planned on attempting it myself.

However, I'm wondering if I might be able to get some help.

I'm currently living between Evansville, IN (1hr away) and Louisville KY (also 1hr away). I'd also be willing to drive 1hr south to Bowling Green, KY, or an hr north into Indiana.

Are there (or does anyone know of any) knifemakers in the area that might be able to heat treat it it for me?

feel free to PM me,if you don't want to post.

thanks a bunch!

Thanks!

I'm thinking about heat treating this O1 knife. I had planned on attempting it myself.

However, I'm wondering if I might be able to get some help.

I'm currently living between Evansville, IN (1hr away) and Louisville KY (also 1hr away). I'd also be willing to drive 1hr south to Bowling Green, KY, or an hr north into Indiana.

Are there (or does anyone know of any) knifemakers in the area that might be able to heat treat it it for me?

feel free to PM me,if you don't want to post.

thanks a bunch!

Thanks!