You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

WIP -- 1st knife from scratch

- Thread starter seionage

- Start date

looks great just 1 word of advise i think every maker will agree with me on is keep it !!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!! DONT SELL OR GIVE IT AWAY YOU WILL REGRET IF YOU DO

I was actually thinking of giving it to my mom. She loves to gun deer hunt, and she really doesn't have a skinning knife.

heat treating!

yaaaa! I got the knife heat treated. Today was a special treat for me. I was invited over by Ken Coats place.

He invited me over to do the heat treating.

Let me say, this was a great vist. I was humbled by Ken's work, craftsmanship, and a friendly personality.

He opened up his shop to me, to let me look around, and he took the time to explain things to me.

I just can't say enough about how nice he was and the vist.

You can tell he really knows his stuff. I've always had an unwritten rule, that you call tell a craftsman,

by the number of jigs he has around his place. Let me tell you, this guy has it all. He as put his time in.

I'm not big on folders, but just holding his knifes makes me rethink that mentality. wow.

So, while Ken was graciously talking to me, he fired up his evenheat oven to 1450.

He let the knife soak for 10min (or was it 15?), and then quenched in oil.

I still need to temper the blade.

After the knife had cool down, he just touched it with a belt, so that

I would have a shiny surface to watch for straw color while I'm tempering.

Knife after heat treat

handle area

a close-up of the bolster area.

yaaaa! I got the knife heat treated. Today was a special treat for me. I was invited over by Ken Coats place.

He invited me over to do the heat treating.

Let me say, this was a great vist. I was humbled by Ken's work, craftsmanship, and a friendly personality.

He opened up his shop to me, to let me look around, and he took the time to explain things to me.

I just can't say enough about how nice he was and the vist.

You can tell he really knows his stuff. I've always had an unwritten rule, that you call tell a craftsman,

by the number of jigs he has around his place. Let me tell you, this guy has it all. He as put his time in.

I'm not big on folders, but just holding his knifes makes me rethink that mentality. wow.

So, while Ken was graciously talking to me, he fired up his evenheat oven to 1450.

He let the knife soak for 10min (or was it 15?), and then quenched in oil.

I still need to temper the blade.

After the knife had cool down, he just touched it with a belt, so that

I would have a shiny surface to watch for straw color while I'm tempering.

Knife after heat treat

handle area

a close-up of the bolster area.

SBuzek

Well-Known Member

It should be fine,You need to get an oven thermometer to put in your toaster oven to verify temps,the surface color will vary by traces of oil and contaminants on the blade.

If you had cleaned off all the scale and got it to shiny metal and cleaned it well then it may have gotten to a straw color.

Stan

If you had cleaned off all the scale and got it to shiny metal and cleaned it well then it may have gotten to a straw color.

Stan

J S Machine

Well-Known Member

Just noticed this thread and I'm looking on my phone so I can't see everything. Just wanted to say that I think that you are doing a god job and keep up the good work.

blade

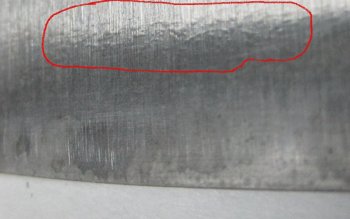

Ken touched the blade on his KMG for me, so that I had a clear spot to watch the color during tempering.

this left a little low spot. I had to take it down a bit with the 220.

blade with the low spot

15min later with some 220 and elbow greese.

You will also notice the brass bar stock that is wrapped in the 220. I'm going to use that in a little bit to start my bolsters.

Ken touched the blade on his KMG for me, so that I had a clear spot to watch the color during tempering.

this left a little low spot. I had to take it down a bit with the 220.

blade with the low spot

15min later with some 220 and elbow greese.

You will also notice the brass bar stock that is wrapped in the 220. I'm going to use that in a little bit to start my bolsters.

3/16 bolsters

I'm using 3/16" barstock for my bolsters? Why? I don't know. I thought it sounded good at the time. My blade is 3/16 thick, so I figured thats what the bolsters should be. I'm using a 5/32 for pins.

I decided to cut the pins to be 3/4 of an inch. I figured that would give me enough length, for when I pein them down.

The pins were a bit large. I don't know how much, as I don't have a micrometer. So, I put them them in the drill and sanded them down, until there was a smooth, but snug fit it the knife.

I'm using 3/16" barstock for my bolsters? Why? I don't know. I thought it sounded good at the time. My blade is 3/16 thick, so I figured thats what the bolsters should be. I'm using a 5/32 for pins.

I decided to cut the pins to be 3/4 of an inch. I figured that would give me enough length, for when I pein them down.

The pins were a bit large. I don't know how much, as I don't have a micrometer. So, I put them them in the drill and sanded them down, until there was a smooth, but snug fit it the knife.